parametrization procedure for jaw crusher tooth plates

parametrization procedure for jaw crusher tooth plates | jaw crusher

parametrization procedure for jaw crusher tooth plates | simons cone crusher 425 pin bushing +86-21-51393804. Black Jaw Crusher Teeth Plate, Rs 45000 /piece Ajit Stone Crusher. Crusher Jaw Plate. ₹ 70 / Kg. By Preet Tradelink Talod Road, Talod, Gujarat. In order to cater the variegated demands of our clients, we are offering an excellent

Crusher Close Side Settings - 911 Metallurgist

In the standard gyratory crusher this is accomplished very simply by increasing the thickness of the concaves at the top, and tapering them down

Computer Aided Design and Analysis of Swing Jaw Plate of

The jaw crusher is primarily a compression crusher while the others operate primarily by the application of impact. Crushing is the process of reducing the size

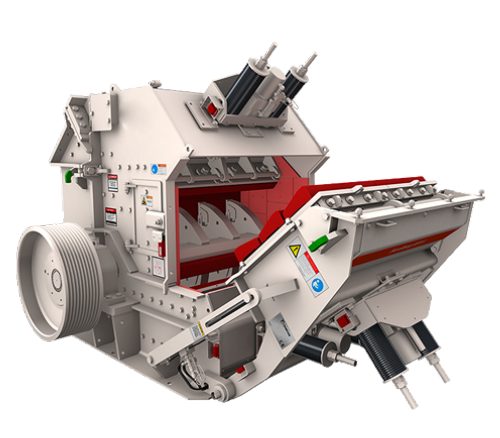

jaw crushers for all your needs - Lutze Process

All our jaw crushers are of the single toggle type, with a deep, JAW CRUSHER. A deflector plate at the top of the moving jaw ST: Sharp Teeth.

Jaw Crusher: Mineral process & Sand production | Sotecma

Both the mobile and fixed jaws have a removable and reversible anti-wear cast iron plate. Toothed design to improve the efficiency of the crushing. The mobile

parametrization procedure for jaw crusher tooth plates | barmac spare

Jaw plates [jaw dies], cheek plates, toggles, and toggle seats. Design and Analysis of Reciprocating Screw for Injection. Parametrization procedure for jaw crusher tooth plates . June · Gornyi Zhurnal. A. D. Kolga; E. Yu. Degodya; D. M. Aybashev; K. Yu. Habarov; From the analysis of operation of jaw crushers

Crushing, screening, feeding and plant solutions

Traylor and Fuller-Traylor gyratory crushers of the early available from to meet any process requirement. Swing Jaw Wear Plate.

parametrization procedure for jaw crusher tooth plates | GP300 GUIDE

CRUSHER JAWS, TEETH AND CUTTING BLADES Crusher jaws Crusher jaws are operated by the hydraulic cylinder of the crusher. One jaw is fixed and the other, equipped with breaking tooth, is moving. Crushing is performed us-ing the crushing teeth of the jaws. Insmart Jaw Crusher for primary size reduction from -150 mm to -3mm. Jaw Crusher Machine, Small Jaw Crusher, Portable Jaw Crusher, Jaw Crusher for Sample Preparation. Working Principal of Jaw Crusher.

Evaluating the Impacts of Jaw Crusher Design Parameters by

jaw crusher by a simpler and faster way, simulation. The process of size and moving jaw plates, measured from a tooth top on one jaw.

parametrization procedure for jaw crusher tooth plates | kueken crusher

6. installation of tooth plate. jaw crusher tooth plate is directly for crushing ore parts. its structure is simple, but because of frequent contact with the ore, tooth plate is the crusher wear quickly. so it is often needed to replace the parts. there are two kinds of cross-section structures shape of the tooth plate, the smooth surface.

parametrization procedure for jaw crusher tooth plates tm100 crusher parts

parametrization procedure for jaw crusher tooth plates TK11422V WEAR PLATE INST Safe Exam Browser / SVN / [r3221] /tags/win/1.8.2. Download this file. 56054 lines (56053 with data), 609.7 kB. What is the reason for the fast wear of jaw crusher tooth plate. Jaw crusher is commonly known as jaw crusher, also known as tiger mouth.

+86-21-63353309

+86-21-63353309

Leave a Comment