spiral bevel gear

Home - Spiral bevel gear

A Spiral Bevel Gear are used to transmit power between shafts that are at a 90-degree orientation to each other. Also, these custom parts are engineered with precision teeth which have a

Spiral Bevel Gear - Calculation of Strenght | PDF - Scribd

It will be seen that the term" spiral bevel gear" is not really appropriate. However, it is in general use and found in many standards. Clearly. only a section of the epicycloid is applicable to tooth shape. since the curve forms loops. In actual production. certain ranges of the curve would impose impossible cutting conditions.

Difference Between Straight Bevel Gear and Spiral Bevel Gear

For same material, size and tolerance, spiral gears are 1.2 - 1.5 times costly than straight bevel gears. Cost difference increases when gear size is small due to difficulty in manufacturing. High finishing requirement may also lead to broader price difference. Thrust force: Two mating gears always exert force on the bearings that mount the shafts.

Bevel Gears - Configure and purchase - MISUMI

JIS B 1704 grade 3 spiral bevel gear. Module m1.0 / 1.5 / 2. Volume Discount. 2D / 3D CAD data available.

Spiral Bevel - 3-d Gear Models and Software

Spiral Bevel Gear program description. Microsoft Excel program with VBA macros. Input gear data into Excel. Run macros to generate IGES file of the tooth surface. Use the IGES to cut teeth on your gear blank in CAD. This program generates tooth surfaces for spiral bevel gears commonly known as Gleason and Klingelnberg. Two programs: for Gleason

Spiral Bevel Gear - Eltrex Motion

Spiral Bevel gears are conical gears with straight teeth. The most important application of this transmission is in applications, similar to the

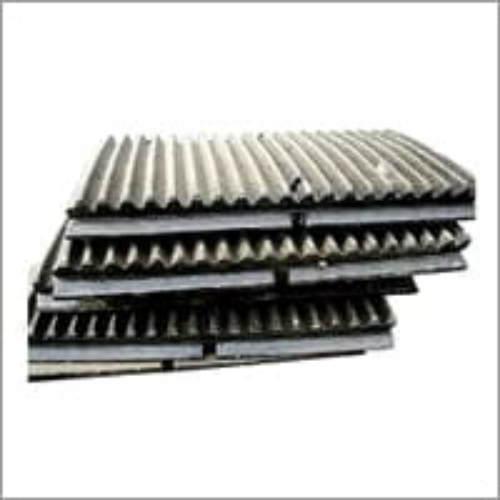

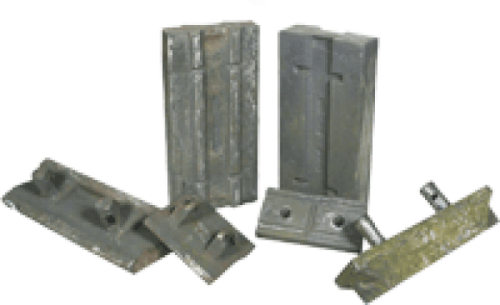

Spiral Bevel Gear Cutters Manufacturers & Exporters in India

Spiral bevel gears are bevel gears that have helical cut teeth. The procedure for machining spiral bevel gears is more troublesome than regular bevel gears. In spiral bevel outfit cutting a bend or helix must be cut in the meantime as the bevel.

Design and Analysis of a Spiral Bevel Gear - Semantic Scholar

In this chapter, the geometry of the main types of spiral bevel gears is first defined and considerations about the spiral angle are made and two approaches

Customizable Precision Spiral Bevel Gear Industrial Bevel Gear

China Customizable Precision Spiral Bevel Gear Industrial Bevel Gear, Find details about China Sprocket, Worm Gear from Customizable Precision Spiral Bevel Gear Industrial Bevel Gear - Qingzhou Jianfu Gear Co., Ltd.

Spiral Bevel Gear at Best Price in India - IndiaMART

Spiral bevel gears are used often in vehicle transmissions as drive from the driveshaft must be turned 90 degrees to drive the wheels. Vishnuvisai Engineering &

PDF Spiral-Bevel Gear Noise: An Approach to Solving In-Field IssuesPDF

non-generated gear spiral-bevel gearset is used to validate the approach. While the pinion convex tooth flank could mesh at different torque levels without undue noise up to 3,400 rpm, the pinion con-cave flank exhibited significant noise at around 1,400 and 3,200 rpm. The spiral bevel gear modeling soft-ware was used to calculate new pinion

+86-21-63353309

+86-21-63353309

Leave a Comment