why do you need to know the specific cutting force for a workpiece material?

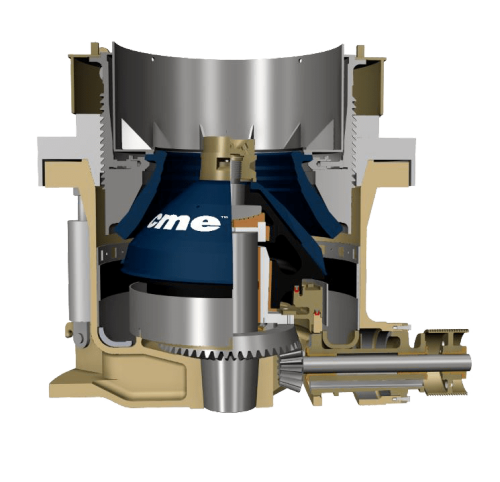

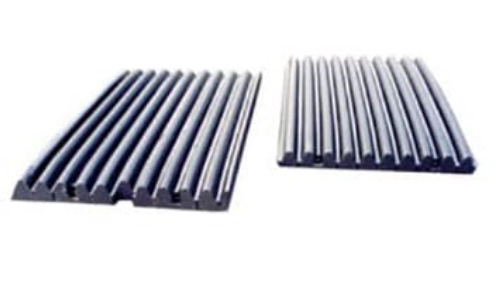

exsample of crusher spare parts | why do you need to know the specific

Easy to transport mobile concrete plants have axles and tires in its main chassis. Thanks to pre-assembled structure, they can be installed in a very short period of time (1-2 days) View Details

HC84 SEAL OIL, PINIONSHAFT | why do you need to know the specific

Jun 29, · Well I found a oil leak . The Oil is coming out the brake pedal shaft. I would like advice if you have changed them, there are 2 but only one is leaking at this time. But I bet both will once the grease gets loosen up. The way it looks to remove the

Specific Cutting Force - an overview | ScienceDirect Topics

The specific cutting force coefficients depend on the part material and the substrate, coating, rake angle and helix angle of the tool.

Cutting Formulas | Introduction to Machining - Keyence

Introduction to Machining” is a site where users can learn about Workpiece material, Tensile strength (MPa) and stiffness, Specific cutting force Kc

HP300 ADAPTER GG106-NP08-04 why do you need to know the specific

Do you want a quick quote for this part GG106 NP06 08? All you have to do is fill out the form. All fields are required. hsp storm parts who owns mp1000 outp mod 1746-ow16 compartment ceramic ball mill 1746-ow16 wiring diagram.

Cutting Speed Chart for Different Materials in Turning, Drilling

Apr 20, · Cutting speed, also known as surface speed, refers to the speed at the outside edge of the tool as it is cutting. It is measured in surface feet per minute (SFM). Cutting speed is mainly depending on the type of materials and cutting tools, related to their hardness. The harder the material, the slower the cutting speed should be.

Formula to calculate cutting process|A.L.M.T. Corp

Formula to calculate cutting process|A.L.M.T. Corp. has been meeting needs of society over half a century with tungsten and molybdenum that are materials

Measuring cutting forces in drilling operations | Kistler

Why measure cutting forces in drilling operations Drilling generates exceptionally high thermal loads on workpieces and on the tools. Moreover, force measurements give an understanding of the tool wear mechanisms, machine-process abnormalities. Thus monitoring and control of the forces will improve the process.

Specific Cutting Force (KC & KC1) - Machining Doctor

Specific Cutting Force (KC1 or KC1.1) Each material has a Specific Cutting Force coefficient that expresses the force in the cutting direction, required to cut a chip area of one square

Lathe: Cutting Forces, Speed and Turning Problems | Industrial Engineering

1. Work Material: The cutting forces vary to a great extent depending upon the physical and mechanical properties of the material. Tangential force can be determined by multiplying the chip cross-section with the specific cutting resistance offered by the work material, which is found to be decreasing with increasing chip thickness and increases with increase in tensile strength

Machinability and The Specific Cutting Force for Work-piece Materials

Two sets of factors are the condition of work-piece materials and the physical properties of work-piece materials. The condition of the work-piece material includes eight factors: microstructure, grain size, heat treatment, chemical composition, fabrication, hardness, yield strength, and tensile strength.

+86-21-63353309

+86-21-63353309

Leave a Comment