high chromium cast iron properties

High Chromium Cast Iron: Part One | Total Materia Blog - Key to

The mechanical properties of High chromium cast iron HCCI mainly depend on type, size, number, morphology of hard carbides and the matrix structure (γ or α). The hypereutectic HCCI with large volume fractions of hard carbides is preferred to apply in wear applications. However, the coarser and larger primary M7C3 carbides will be precipitated

High chromium cast iron pipe | Abrasion resistant pipe

High chromium cast iron (containing 12% chromium >) is an excellent wear resistant material.In the research of high chromium cast iron, generally focus on high chromium cast iron such as Cr15, Cr20.With the increase of Cr content and the addition of various alloying elements, the influence on the change properties of the structure was studied.

Wear-resistant high chromium cast iron pipes

Description Wear-resistant high chromium cast iron pipes are composed of 2 layers of metal, the outer layer is generally Q235 ordinary steel pipe, and the innerHigh chromium alloy,Optional welding and cutting, high wear resistance and heat resistance.

High Chromium Cast Iron: Part Two :: Total Materia Article

High chromium cast irons (HCCI's) exhibit very good mechanical properties and offer benefits for a range of manufacturing applications.

JP5753365B2 - High chrome cast iron - Google Patents

cast iron less hardness chromium cast high chromium Prior art date 2010-10-29 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Active Application number JP2010243956A Other languages Japanese (ja) Other

High Chromium Cast Iron: Part One | Total Materia Blog - Key to Metals

The mechanical properties of High chromium cast iron HCCI mainly depend on type, size, number, morphology of hard carbides and the matrix structure (γ or α). The hypereutectic HCCI with large volume fractions of hard carbides is preferred to apply in wear applications. However, the coarser and larger primary M7C3 carbides will be precipitated

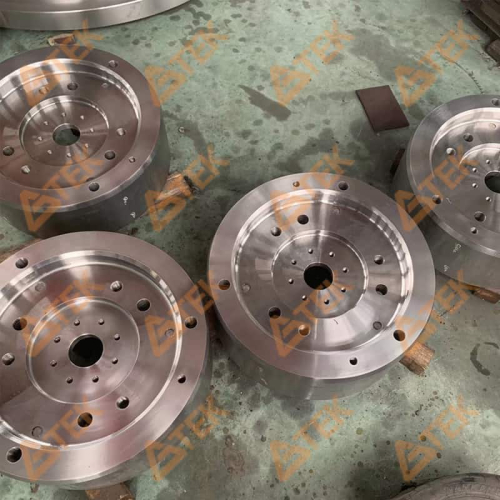

Hi-chrome Iron Alloy | Hi-Chrome Casting | Hi-Chromium Alloy

WSF can produce for you a 15% and 25% Hi-Chrome alloy iron. Typically used in applications of wear resistance and long term heat resistance are required, such as impellers, turbines, and grinding applications. The iron expresses a very hard surface. These high-chromium alloys attribute their superior hardness to the presence of chromium carbides.

Study of the Structure and Properties of High-Chromium Cast Irons and

With respect to mechanical properties (σ r = 480 MPa; hardness 290 -340 HB) high-chromium cast iron surpasses high-silicon cast irons . In as number of cases chromium cast irons are additionally alloyed with molybdenum. Molybdenum in white cast iron is within eutectic carbide and matrix phase.

Diffusion behavior and mechanical properties of high chromium cast iron

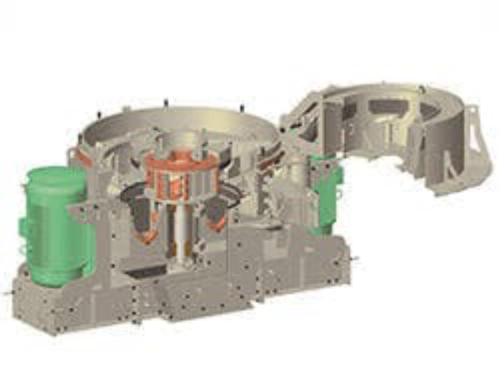

1. Introduction High chromium cast irons (HCCIs) are primarily used in mining machinery, wear resistant lining board, crusher jawplate, etc. because of their excellent wear resistance and high hardness [1], [2], [3]. But the poor toughness restricts their further development [4], [5].

Properties of sintered WC-(high chromium cast iron) alloys; WC-kokuromu

Made available by U.S. Department of Energy Office of Scientific and Technical Information

Ductile iron vs stainless steel corrosion - zbt.yachtsupply.shop

If the carbon level in the steel is too high, chromium can combine with carbon to form chromium carbide. This occurs at temperatures between about 450-850 C. car paint repair near me american horror story season 8 cast warlocks Find Your Wi-Fi Password hampton inn customer service baltimore mania 2023 knifemakers guild show 2022 research

+86-21-63353309

+86-21-63353309

Leave a Comment