spiral groove machining

US7223054B1 - Spiral groove pipe joint machining assembly

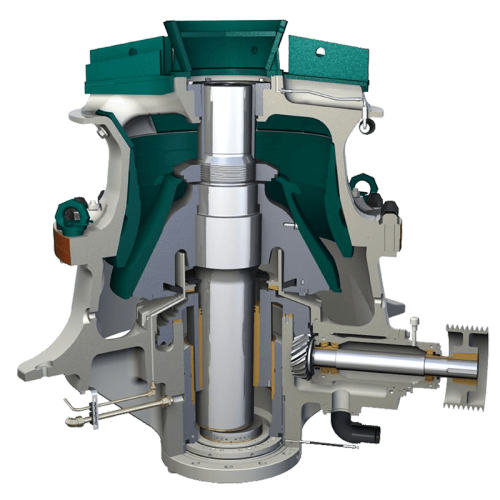

A spiral spline groove machine apparatus for manufacturing a sealed spiral spline pipe connection by machining spiral grooves into the bell and spigot end of a length of pipe. A

JPH07314257A - Spiral groove working method and working machine

In the spiral groove machining method according to the present invention, the groove pitch of the tubular work piece is set to be the same pitch by keeping the rotation ratio of the rotation drive

Spiral Groove Taps (Blind Hole Machining) - MZG Official Store

Shopping for Cheap Spiral Groove Taps (Blind Hole Machining) at MZG Official Store and more from on Aliexpress.com ,the Leading Trading Marketplace from

Unicom Spiral Grooving

22/02/ · Unicom 7000 cnc machining centreIdeal for spiral groove on valve flanges

CN108971588B - Spiral groove machining blade, manufacturing method and

The invention discloses a spiral groove processing blade, a manufacturing method and a milling cutter using the blade, wherein the manufacturing method comprises the following steps: s1: according to compressionDetermining the molded line of the end face of the spiral groove of a screw rod to be processed in a machine; s2: solving a helicoid equation and a spiral parameter; s3: solving

Problem: how to machine a spiral groove in a flat disk (like a

03/07/ · Probably we all do. The latest seizure involves a spiral groove on a 6" diameter flat disk, conceptually like the groove on a record. But, I want it to advance 1/2" per revolution, from an initial 1" radius offset from the center out to 3" radius offset, and the groove needs to be about 1/8" wide by 1/8" deep.

Programming: Turning a Spiral Along a Crowned Cylinder

19/10/ · Programming: Turning a Spiral Along a Crowned Cylinder. A recurring job may come up that involves turning a helix/spiral groove in a "cylinder" with a radius on the walls. Like a crowned roll, convex. I'm trying to figure out exactly how to program such a part in a CNC lathe. I have MasterCAM experience, X2 and lower, some 3D milling of mold

Active Profiling and Polishing Model and Validation Based on

The spiral groove of the revolving body is modified and polished. a helical trajectory, are studied, and the polishing cutting process

Shaft Spiral Groove Machining Parts Provider,Custom Shaft Spiral Groove

Stainless Steel Hollow Tube Shaft Spiral Groove Machining Components. As 316 stainless steel components for assembly pulley used on the food processing machine. It required a strict roundness for twirling. Meanwhile, this part is processed in one go and precise in the location required to be machined within the strict tolerance.

Flange Face Finish, Stock Finish, Spiral Serrated finish,Smooth

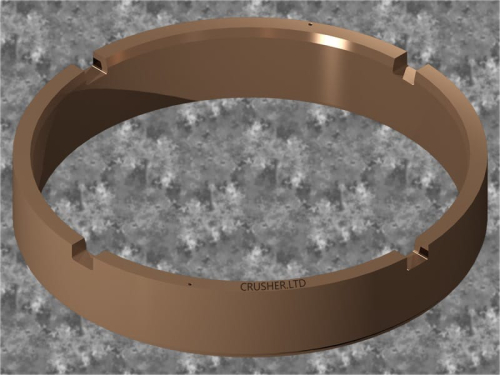

A serrated finish, either concentric or spiral, is required with 30 to 55 grooves per inch and a resultant roughness between 125 and 500 micro inches. This allows for various grades of surface finish to be made available by flange manufactures for the gasket contact surface of metal flanges. The picture shows a serrated finish on a Raised Face.

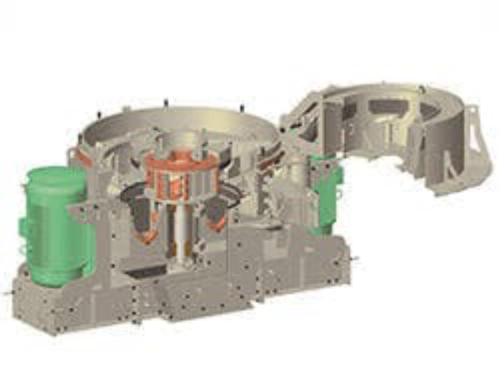

A Study on Spiral Groove Grinding with Dish Wheel

This technology also makes the spiral groove virtual machining possible. The technology is also a real DFM (Design For Manufacture), because the design

+86-21-63353309

+86-21-63353309

Leave a Comment