gyratory crusher maintenance

GYRATORY CONE CRUSHER SHUTDOWN

21/4/ · #viral #viralvideos # ironore #kobelcogyratoryconecrusher #kobelcocrusher #ironoremining #ironorecrushing #ironoreprocessing #maintenance #shutdownma

Primary Gyratory Crusher Maintenance - Crushing, Screening

My questions are regarding to maintenance of the primary gyratory crushers. Does anybody know any kind of sensor to monitoring head spin of the main shaft of the primary gyratory crusher?

Cone Crusher Maintenance - Rock Products Magazine

Cone Crusher Maintenance · Choke Feeding is a Must · Make Oil Lubrication Systems a Top Priority · Use the Correct Oil · Inspect the Main Frame

Gyratory crusher type ts tsu 7500762 m 8 rev 0 item

GYRATORY CRUSHER TYPE TS TSU 7500762 M 8 Rev 0 Item Task Repairs Required Date from CP 261 at Chile Technological University of Professional Institute of Technical Training Center, Valparaiso

PDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crush - ing chamber below.

What Are the Differences Between The 7 Types of Crushers?

20/7/2022 · If you only want to crush more raw material with more than 1000t/h and no special demands on final particle shape, you can choose gyratory crusher. Because it can be fed with two sides, which greatly reduces crushing time and improve crushing ratio thus saving lots of energy cost. Note: If ton/hr<161.7 (gape in meters)∧2, use a jaw crusher.

Crusher maintenance services

Close examination and good maintenance of your crusher protects your plant's overall productivity. By acting fast, you can avoid poor performance, stoppages and costly repairs. Our regular crusher inspections and ongoing technical support ensure your equipment keeps operating at maximum efficiency.. In addition to these comprehensive inspections, our crusher maintenance services include

2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing

The parameters used in the basic design of a gyratory crusher are nip angle, feed rate, feed opening, closed-side setting, work index, and horsepower. The combination of the nip angle, feed opening, and closed-side setting determine the length of the crushing chamber and indirectly the length of the main shaft.

Jaw crusher maintenance - Pit & Quarry

Check jaw dies daily, making sure bolts are kept tight. Check cheek plates for any excessive wear that may affect the mainframe of the jaw.

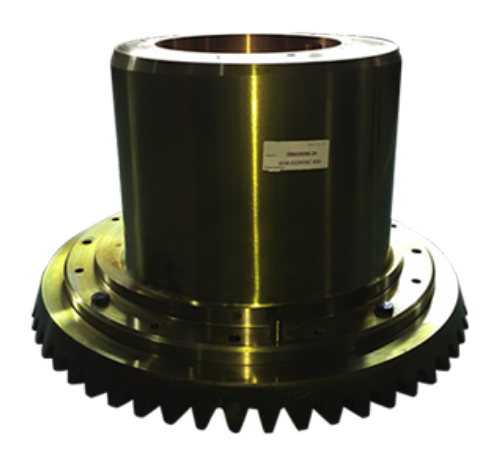

Gyratory Crusher

why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs. Simpler Operation and Maintenance. Sufficient Supply of Spare Parts, Worry-Free Operation. Strong Adaptability, Applicable for Severe Crushing Conditions. Able to Work Continuously under High Intensity, It has longer service life.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

To prevent machine failure, Schmidt offers tips on horizontal shaft impact (HSI) crushers and cone crushers. Perform Daily Visual Inspections.

+86-21-63353309

+86-21-63353309

Leave a Comment