hammer mill wear plates

Hammer Mill Wear Parts - Wear Parts For Industry

If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed and warranted replacement parts for your hammer mill. Tough. Durable. Cost-efficient. Qiming

Wear Parts - Rightway Manufacturing

We maintain a large inventory of wear parts compatible with most conventional hammermills. Experienced welders and metal fabricators on hand. We can fabricate just about any part needed for your hammermill. Call us at 1-800-866-6455 (toll free) or 870-673-7226 to discuss your particular needs.

Hammer Mill Wear Plates | Products & Suppliers

Used to attach wear plates, blades, teeth and other parts to heavy equipment. Other applications are mill hammers, crusher liners, dipper teeth and lips, dragline buckets, railroad switches and

Hammer Mill Wear Plates Manufacture and Hammer Mill Wear

Hammer Mill Wear Plates - manufacturer, factory, supplier from China (Total 24 Products for Hammer Mill Wear Plates) Customized Hammer Head Of Mining Crusher Hot Sale. Brand:

Hammer Mills Wear Parts | Crusher Mills, Cone Crusher, Jaw Crushers

Find Hammer Mill Wear Plates related suppliers, Ball Mill Unicast supplies Our wear parts include: Grinding Mill/ Ball Mill Valves Diverter Valves. hammer mill parts manufacturer - wear parts.

wear plates Archives - Schutte Hammermill

2016. 10. 27. · Replacing Hammer Mill Wear Parts Any machine that has moving or rotating parts requires routine maintenance to ensure that it performs at optimal capacity. This is especially

Replacement Wear Parts - Schutte Hammermill

Replacement wear parts for hammer mills and shredders, including hammers, screens, discs and cutter teeth, wear plates, bearings and more. Request A Quote. 1-800-447-4634. MENU MENU.

Mini hammer mill double wear-resistant plates hammer grinder machine mill

1. Adopting steel plate welding structure, the hammer mill rotor and the motor are mounted on the same base, and the serpentine spring coupling is directly connected to the transmission, and the transmission efficiency is high; 2. The base is welded with thick steel plate and reduces the center of gravity of the spindle to effectively improve the vibration phenomenon; 3.

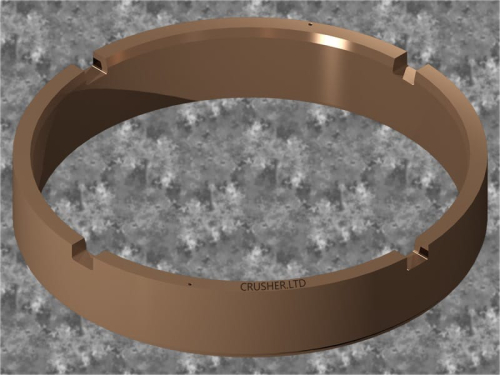

Hammer Mill Wear Plate

Hammer Mill Wear Plate. A rotor with hammers is the main working part of a coal hammer mill. The rotor consists of main shaft disk hinge pin and hammers. A sieve plate lies below the rotor. The motor drives the rotor to rotate at a high speed. Typical Hardox applications for coal crusher hammer mills are the hammer

Wear Plates Hammer Mill

Plates Hammer Mill ; Hopper Edges; Wear ApronsInserts Rolling Mill Guides; CCO Wear Liners. As a genuine mining and quarrying wear liner support service, REXLINE™ have excellent quality CCO plate and weld wires. The microstructure of Cr7C3 carbide volume fraction is 50% or more which makes it one of the reliable CCO Liners on the

Design and Fabrication Of Hammer Mill Mechanical Project

The study of project deals with the hammer mills employing a high speed rotating disc, to which an 'n' number of hammer bars are fixed and swung outwards by centrifugal forces.Material is fed in, either at the top or at the Centre, and it is thrown out centrifugally and crushed between the hammer bars or against breaker plates fixed around the periphery of the cylindrical casing.

+86-21-63353309

+86-21-63353309

Leave a Comment