gyratory crushers sizes

PDF) Modelling the crushing-sizing procedure of industrial gyratory crushers

2006/10/9 · Tsakalakis, K.G., 1990, Product Size Distributions of Industrial Gyratory Crushers, Mining and Metallurgical Annals, Vol. 75, pp.41-48, (in Greek with English abstract). Mineral Processing

Superior™ MKIII Series primary gyratory crushers - Outotec

Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to the Outotec Outotec Superior™ MKIII crushers brings up to 70% reduction in downtime. Crusher maintenance downtime has also produced a significant size

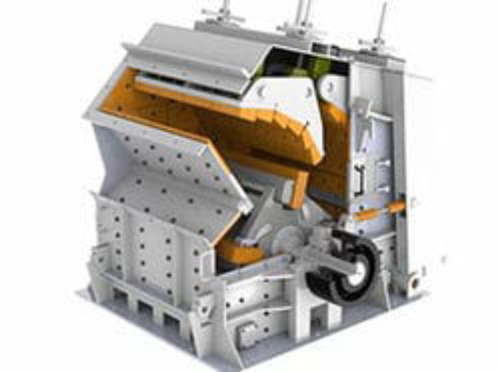

Compression mining crushers | Primary crushers

Incorporate our engineering expertise into any and all of your crushing systems, no matter the size, up to and including systems for total plant. We can provide you with compression crusher parts as well as complete compression crusher machine units, such as gyratory crushers, jaw crushers and cone crushers.

Torque Analysis of a Gyratory Crusher with the Discrete

selection of the minimum resolved particle size are given. Keywords: comminution; gyratory crusher; discrete element method; torque;

Gyratory Crusher Liners

Maximise your crushing productivity with proven Gyratory Crusher Liners. Our Gyratory Crusher Liners are focused on serving you and your operation and are tailored specifically to your needs and goals. Rely on our knowledge, engineering and technology to improve

jaw crusher and gyratory crusher | Henan Deya Machinery Co., Ltd

7/29 · A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface. The compression is created by forcing the rock against the stationary plate. The opening at the bottom of the jaw plates is the crusher product size gap. The rocks remain in the jaws until it is small enough

Gyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Difference Between Jaw Crusher and Gyratory Crusher

The request of input particle size of the jaw crusher is strict. After blasting, it is necessary to impact and crush the big stone to meet the requirement of

Gyratory Crusher Sizes Manufacture and Gyratory Crusher Sizes

China Gyratory Crusher Sizes Manufacture, Visit Here to Find the Gyratory Crusher Sizes That You are Searching for. Shenyang Sanland Mining Equipment Manufacture Co., Ltd. [Liaoning,China] Business Type: Manufacturer Main Markets: Africa , Americas

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

Key features. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h. Cyclo-palloid spiral bevel gear. Higher-capacity drive motors if required. Rugged design. Direct feed possible. High throughput rate. Optimum degree of comminution. Stroke can be changed by adjusting the eccentricity. High

Industrial Solutions Gyratory crushers - ThyssenKrupp

coarsely crushed material is then reduced to the desired product size in the crush - ing chamber below. Jaw gyratory crushers can handle much bigger chunks of material than comparable

+86-21-63353309

+86-21-63353309

Leave a Comment