coal pulverizers

coal pulveriser - SlideShare

6. FIRING DIRECT FIRING Coal is ground and is directly carried from the Pulverizer to the Furnace by use of Pressurized air. Pressurized Air from Primary Air Fans goes to the Pulverizers. Sufficient temperature is maintained for drying of coal and moving the Pulverised Coal to the furnace without settling. 7.

Get Latest Worldwide Coal Pulverizers Market Research Study by HTF MI

Worldwide Coal Pulverizers Market In-depth Research Report 2022, Forecast to 2028. HTF3413447. Report Format PDF. Pages 112. Views

Coal mill pulverizer in thermal power plants - SlideShare

3. 2.Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the

CE-Type Pulverizers / Mill » Babcock & Wilcox

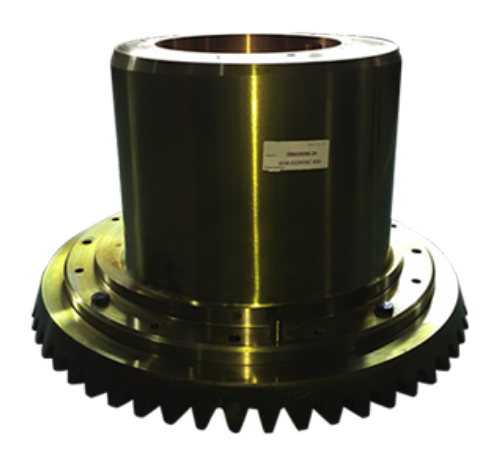

Roll Wheel Pulverizer B&W has designed, manufactured and placed in operation more than 1,100 roll wheel pulverizers, grinding a wide range of coals at power stations throughout the world.

Coal Pulverizer Manufacturer | Pulverizing System | Williams Crusher

COAL PULVERIZERS FOR SOLID FUEL COMBUSTION As one of the world's leading coal pulverizer manufacturers, Williams has the most advanced direct fired coal and pet coke pulverizing system in the field today. Design features of our coal pulverizer emphasize improved system reliability, constant product size control, and reduced energy requirements.

Coal Pulverizers Wear Liner - WALDUN | Abrasive Enhanced

Coal pulverizers wear liner is used to protect the cylinder from direct impact and friction of the grinding body and materials. At the same time, different types of liners can be used to adjust the movement state of the grinding body to enhance the abrasive effect of the crushing body on the materials. It is helpful to improve the crushing

Coal Pulverizers - ASME - American Society of

This Code applies to the pulverizing system as a whole, including all the component parts necessary to take the raw coal, hot air and tempering air at the system inlet, and deliver

How Vertical Grinding Mills Work (Coal Pulverizer Example

Coal Pulverizer Purpose A coal pulverizer is designed to classify, dry and grind coal. It is beneficial to dry, grind and classify the coal prior to it entering the furnace as this gives much more

PDF COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS OF LOW NOx BURNERSPDF

Coal pulverizer design and operation is an important element integral to the long term success of Low NOx combustion systems. The increased use of Low NOx burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous

Coal Pulverizers Market Report | Global Forecast From 2022 To 2030

Global Coal Pulverizers Market by Type (Low Speed Coal Pulverizer, Middle Speed Coal Pulverizer, High Speed Coal Pulverizer), By Application (Construction Industry, Metals and Mining, Glass and Ceramics, Other) And By Region (North America, Latin America, Europe, Asia Pacific and Middle East & Africa), Forecast From 2022 To 2030

Southwestern Corporation - Pulverizer, Coal Mill, Coal Power Plant

Southwestern's primary business is the design, manufacture and servicing of performance modifications and upgrades for coal pulverizers. Our work force is experienced and familiar with the requirements and demands of our electric power generation and cement plant customers. As a result, customer service is our top priority.

+86-21-63353309

+86-21-63353309

Leave a Comment