anti friction coating spray

MOLYKOTE® Anti-Friction Coatings, DuPont - ChemPoint

Product Description. Protect your components with long-lasting, dry-film lubrication. Often described as "lubricating paints," MOLYKOTE® anti-friction coatings (AFCs) provide a dry, slippery film that improves surface roughness and optimizes friction on the wear surface, even under extreme loads and operating conditions.

Anti Friction Coatings | MOLYKOTE® Smart Lubrication™ - DuPont

Anti-friction Coatings: High-performance, long-term, dry film lubrication. Often described as “lubricating paints,” MOLYKOTE® Anti-Friction Coatings contain solid lubricants dispersed

MOLYKOTE™ D-321 R Anti-Friction Coating - Silmid

Molykote D321R is an air-curing dry spray lubricant that can be used for various metal on metal applications to help avoid stick-slip and ageing.

MOLYKOTE® D-321 R Anti-Friction Coating - Molykote

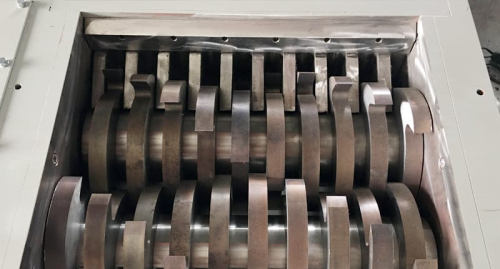

MOLYKOTE® D-321 R Anti-Friction Coating is an easy-to-use air-cured, dry film lubricant engineered for metal-on-metal interfaces in heavily loaded equipment with low to medium speeds. MOLYKOTE® D-321 R Anti-Friction Coating is formulated with solid molybdenum disulfide and graphite to provide excellent resistance against stick-slipping and ageing.

Anti-friction Coatings - Lubricants and Services - BECHEM

BECHEM anti-friction coatings can be applied using standard application methods for industrial coatings, such as spraying, immersion, barrels, brushes, or dip centrifuging. The application

SCOPS Coating Technologies – Clean and Protect

scops Coating technologies. SCOPS has a family of environmentally friendly, long lasting and inexpensive omni phobic coatings and additive. Our coatings create a low friction surface allowing both water and oil based liquids to cleanly and quickly glide over most surfaces. They are self cleaning, optically clear and graffiti resistant.

Spray | Molykote | BriskAsia - One Stop Lubrication Solution

316 Silicone Release Spray. 557. Anti-Spatter Spray (S-1010) CU-7439 Plus Spray. D-321R Spray. Food Grade Spray Oil. G4500 Synthetic Spray. G-Rapid Spray. M-55 Dispersion.

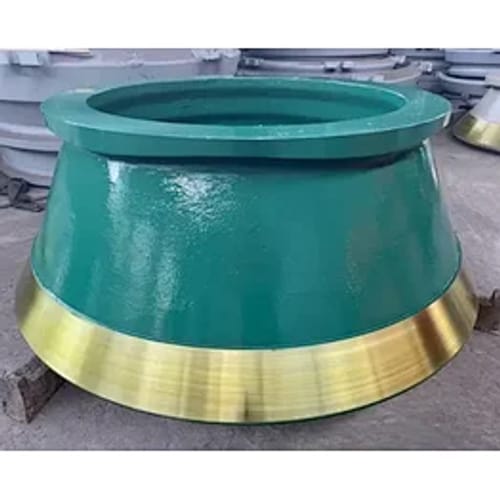

Thermal Spray and Engineered Friction Coatings | Anti-Slip Surface

Thermal Spray and Anti-Slip Surface Coatings Along with the wear resistant benefits of thermal spray, friction coatings can easily be stripped and recoated if a surface wears down without damaging the part. Thermal spray coatings can also be applied without part distortion, warping or cracking.

Friction Reduction Coatings

Most Popular Friction Reduction Coating. Non-magnetic graphite conductive epoxy system. Useful lubricity. Exceptional dimensional stability. High bond strength properties. Superior durability. Volume resistivity 50-100 ohm-cm. Used in EMI/RFI shielding and static dissipation applications. Cost effective. Serviceable from -60°F to +250°F.

High Friction Coating, Nickel Diamond Coating for Metal Parts

STI’s high friction coatings are used on shims, flanges, bolts, connectors, clamps, collets, joints, belt applications, and more. These coatings work to increase the friction, grip, torque, energy transfer and other critical properties of these applications.

MOLYKOTE® Anti-Friction Coatings - Molykote Lubricants by DuPont

Anti-Friction Coatings Protect your components with long-lasting, dry-film lubrication. Often described as "lubricating paints," MOLYKOTE® anti‑friction coatings (AFCs) provide a dry, slippery film that improves surface roughness and optimizes friction on the wear surface, even under extreme loads and operating conditions.

+86-21-63353309

+86-21-63353309

Leave a Comment