stone crushing process pdf

PDF Design of impact stone crusher machine - CitefactorPDF

design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. Impact stone crusher is used with soft materials, medium to hard stones and

rock crusher machinery process principle pdf

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR. In CHP crusher work on principle of combination of impact and attrition crushing.In this type of crushing first coal is break due t

Stone Crushing Process Pdf

Stone Crushing Process Pdf. the influence of stone crushing processes on aggregate ,aggregate shape properties have a direct influence on the behaviour of pavement materials. the crushing process is the main factor .environmental guidelines for stone crushing units stone ,stone crushing industry engaged in producing crushed stones which is the basic raw particulate matter measured between 3 to

PDF 11.19.1 Sand And Gravel Processing - US EPAPDF

emission factors for the crushing, screening, and handling and transfer operations associated with stone crushing can be found in Section 11.19.2, "Crushed Stone Processing." In the absence of other data, the emission factors presented in Section 11.19.2 can be used to estimate emissions from corresponding sand and gravel processing sources.

The Complete Guide to Crushed Stone and Gravel

2019. 11. 11. · Crushed stone: The term “crushed stone” usually refers to stone that has a mixture of stone dust in it. This type of stone is best used for a base when heavy compaction is needed. As a result, it is typically used for the base of concrete and paving projects, foundations of structures, and driveway bases.

298871514-Process-of-Stone-Crushing.pdf - 4 TECHNICAL

View 298871514-Process-of-Stone-Crushing.pdf from POS INTERNATIO at COMSATS Institute Of Information Technology. 4 TECHNICAL CHARACTERISTICS OF STONE CRUSHING PLANT 4.1 PROJECT DESCRIPTION As

Crushing Plant Design and Layout Considerations - Metallurgist & Mineral Processing

2016. 2. 24. · • Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations

Stone Crusher Project Report Pdf | Crusher Mills, Cone Crusher, Jaw

project report on stone crusher pdf - beltconveyers.net. STONE CRUSHER - Facilitating the growth of small enterprises Total Project Cost 1481000 STONE CRUSHER Crushed stone is segregated into various sizes like 35mm

Construction Working and Maintenance of Crushers for Crushing

2018. 12. 26. · 1 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials www.practicalmaintenance.net Construction, Working and Maintenance of Crushers for Crushing Bulk Materials By K. P. Shah Email: kpshah123[at]gmail.com (Please replace [at] with @) Committed to improve the Quality of Life For more articles on mechanical maintenance, visit

Pre-Feasibility Study - Ministry of Commerce

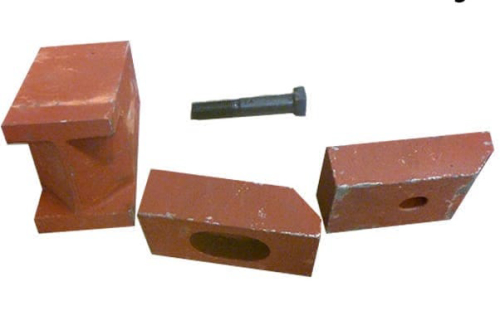

2021. 2. 27. · 5.1 Stone Crushing - Production Process The main machinery involved in the stone crushing industry is Hammer Crusher, Vibrators, Rotor, Conveyers and Support Structure. The

PDF AP-42 Section 11.19.2 Crushed Stone Processing and Pulverized ... - US EPAPDF

11.19.2.1 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite. Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th

+86-21-63353309

+86-21-63353309

Leave a Comment