jaw crusher liner profiles

Best 30 Concrete Crushers in Richmond, TX with Reviews - YP.com

Concrete Crushers in Richmond on YP.com. See reviews, photos, directions, phone numbers and more for the best Stamped & Decorative Concrete in Richmond, TX.

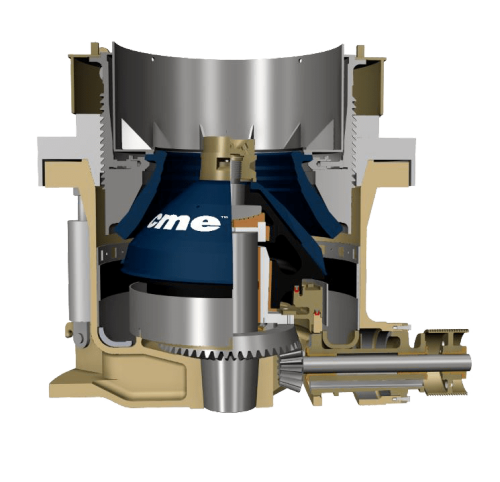

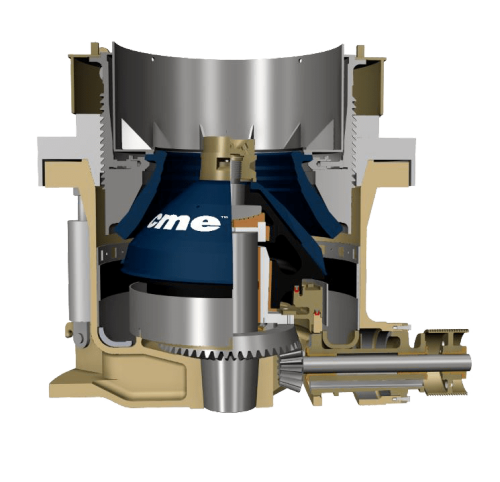

Manganese Crusher Liners - Mining Wear Parts

Will manganese crusher liners optimise my crusher performance? Our aftermarket Manganese crusher liners for cone, jaw, gyratory, and impact crushers are cast

jaw crusher liner profiles | malaysia spare lower head bushing for crusher

Jaw Crusher, Jaw Crusher Manufacturer, Jaw Crusher for 2021-8-19 · Jaw crusher can process a maximum compressive strength of the material tup to 320Mpa, it is widely used in mining, smelting, building material, highway, railway 2015-7-22 · Jaw Crusher Liner Plate Design & Profile Shapes.

Manganese Parts - Australian Crushing and Mining

Whether it be standard profiles, our own modified profiles or perhaps a profile We also are able to supply the following Jaws & Liner Plates to

jaw crusher liner profiles ball mill spare part pdf

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

jaw crusher with jaw plates images

Jaw Crusher Liner Plate Design & Profile Shapes 7 22 These non choking jaw plates have been developed in two styles, reversible and non reversible. The

Jaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

World-Leading Crusher Liners - CMS Cepcor

CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various

jaw crusher liner profiles | part detail hammer mill machinery

Liner wear in jaw crushers. Jan 01, 2003 · 1. Introduction. Jaw and cone crushers are commonly used in the mining and aggregates industry. Today, it is possible to predict the performance of a cone crusher, provided the geometry, crusher settings and the characteristics of the material fed into the crusher are known (Evertsson, 2000).The geometry of the crusher will change because of wear.

Liner wear in jaw crushers - ScienceDirect

01/01/2003 · Using a small jaw crusher, the wear of the crusher liners has been studied for different settings of the crusher. The experiments have been carried out using quartzite, known for being very abrasive. Measured profile (x, and + marks) and corresponding simulated profile (solid line) on moving plate. Closed side setting 5, 3 and 2 mm, feed

JAW CRUSHER LINER

Permanscess stocks a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various

+86-21-63353309

+86-21-63353309

Leave a Comment