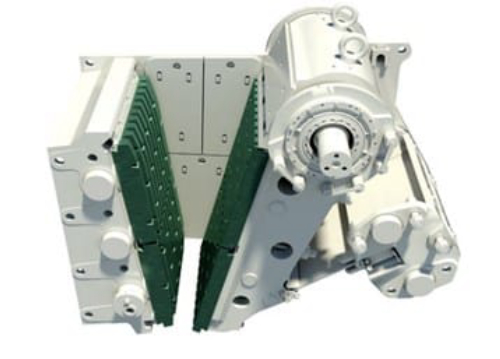

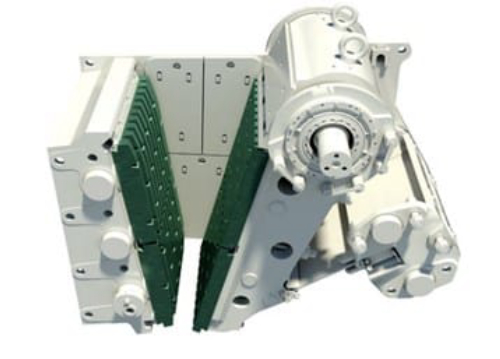

rushing plate profile of jaw crushers with simple jaw movement for crushing abrasive materials

rushing plate profile of jaw crushers with simple jaw movement for

US20100044486A1 - Jaw assembly for a jaw crusher A jaw assembly for a jaw crusher is disclosed where the assembly comprises a jaw stock ( 12 ), a wear plate ( 16 ), and a fastening device in the form of a bolt ( 34 ) with a square head ( 42 ) at one end and a washer ( 56 ) and fastening nut ( 52 ) positioned at an end opposite to the one end.

Crushing it since 1989

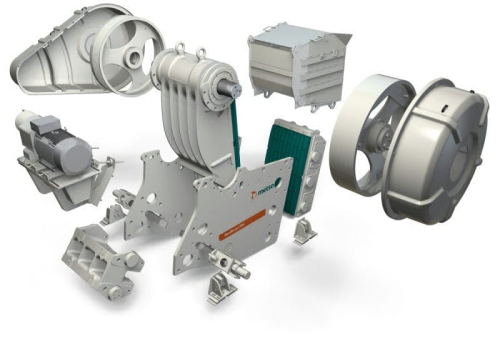

crushing chamber. Single toggle MR Jaw Crusher is designed for application where cost-efficient primary reduction of hard, medium and abrasive material is.

rushing plate profile of jaw crushers with simple jaw movement

Jan 10, · The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed

Jaw crusher - SlideShare

In double there is no rotary motion in the crushing cycle and all crushing is done by compression of the feed material between two massive jaws

Stationary jaw crushers - rockprocessing

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are

PDF) Selected Design Issues of Toggle Plate ... - ResearchGate

The article presents the problem of increasing the performance of the jaw crusher, reducing the crushing power and moment.

Crushing technology - kleemann

Jaw crushers operate according to the principle of pressure crushing. The crushed material is crushed in the wedge-shaped pit between the fixed crusher jaw

PDF) Optimum design and analysis of (the) swinging jaw

Based on the analysis of the liner movement and the crushing parameters, force distribution along the swing jaw plate is obtained.

Jaw Crusher Working Principle - 911 Metallurgist

The combination of favorable crushing angle, and non-choking jaw plates, used in this machine, promotes a much freer action through the

rushing plate profile of jaw crushers with simple jaw movement for crushing abrasive materials

With two jaw plates forming the crushing chamber, jaw crushing machine can simulate the two jaws movement of animals and complete materials crushing. Mainly, jaw crusher is used to crush mineral and large-size material in mining, smelting, building materials, highways, water conservancy and chemical industrial and other fields. Crusher

Application of The New Shape Crushing Plate in Machine

in the jaw crusher and two dead center positions of the moving jaw AA and A1A1. The grain size depends on the. Figure 1: Profiles of crushing plates: a)

+86-21-63353309

+86-21-63353309

Leave a Comment