ball mill liner

The Different Types of Mill Liners You Should Know

All ball mill liners must be very resistant and capable of withstanding high impacts. The milling process uses steel balls to break down the material. The grid liner has the dual role of protecting the cylinder while making the movement of the steel balls effective. Double Wave Liners People also use double wave liners for ball mills.

Mill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

Ball Mill Rubber Liner, The rubber linings produced by AGICO CEMENT can generally be divided into ball mill rubber linings, rod mill rubber linings, tube mill rubber linings, AG mill

How to Replace the Ball Mill Liner?

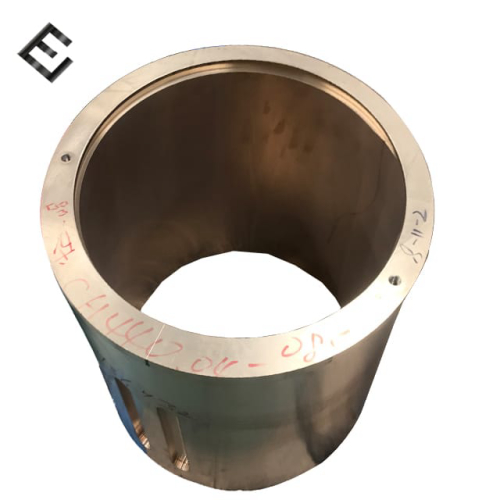

At this time, it is necessary to replace the new ball mill liner. The ball mill liner is intended to protect the barrel of the ball mill in

Billy D Mills, 65 - Hillsboro, OR - Has Court or Arrest Records

Billy Dean Mills, Billy D Mills, Billy A Mills, Billy O Mills, Billy J Mills. Verifacation Engineer at Intel. 503-***-**** View Phone. 7 Visits. Photos. Not the right Billy? View More. LOW HIGH. 0 Add Rating Anonymously. 0 Reputation Score Range. 0.96 3.03 /5. View Actual Score

Steel Ball Mill Liners

In Φ2.2 x 6m ball mill, the capacity is 3.2mt per hour on 2μm∼10μm, which has achieved leading level at home and abroad. In 2000, we designed the first set of the boltless liners applied in a super fine powder vibrating mill in China. In 2003, we designed and manufactured ball mill liners used in the largest super fine powder ball mills

Mill Liner Market Forecast, Trend Analysis & Competition

The liners for ball mills are likely to reflect a healthy rate of growth in sales over the coming years, attributing to the remarkable rise in mineral dressing

DEM modelling of liner evolution and its influence on grinding

DEM used to simulate the dynamics of ball motion in an industrial scale ball mill. ▻ Energy distributions with progressively worn lifter geometry profiles

Selection and Design of Ball Mill Liners

The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction

Mill Liners Manufacturer - MGS Casting

Ball mill liners from MGS Casting maximize the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners available. Refined through ongoing design improvements, our ball mill liners maximize uptime and service intervals while providing an improved crushing of the ore. Our ball mill liners solutions can

Mill Liners | Multotec

Advantages of Multotec's Rubber Mill Liners: Reduced weight compared to steel liners. This results in less we bearings and reduction in torque at start up The reduced weight makes it safe to install liners by hand, eliminating the need for a mill liner handler Rubber linings are applicable for a wide range of applications.

Ball Mill Liners Market Analysis, Forecast, Size, New Trends and

The MarketWatch News Department was not involved in the creation of this content. (Reportmines via Comtex) -- Pre and Post Covid is covered and Report Customization is available. This

+86-21-63353309

+86-21-63353309

Leave a Comment