rock crusher jaws

Jaw Crushers - Parker Plant

First stage, primary rock crushing plants. Parker have been engineering rock crushers for over 100 years and today thousands of jaw crushing machines and units

Jaws Rock Crusher For Sale | Crusher Mills, Cone Crusher, Jaw Crushers

Small jaw crusher is a stone crusher or rock crusher with low energy consumption, easy installation Jaw crushers for sale, Jaw rock crusher supplier - One of the most popular stone-crushing equipments in the world, Jaw Crusher is

Jaw Crushers - high quality and reliability from RETSCH

The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials.

Jaw Crushers | McLanahan

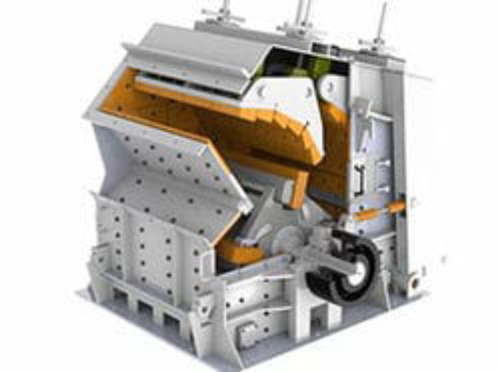

The Jaw Crusher is well suited for a variety of applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, metallurgy, water conservancy and chemical industry. How Jaw Crushers Work 1:59 A Jaw Crusher uses compressive force for breaking material.

Stationary jaw crushers - rockprocessing

Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper,

Used Jaw Crushers for sale. equipment & more | Machinio

42 x 48 in (1 x 1.2 m) Allis Chalmers jaw crusher. USED. Manufacturer: Allis-Chalmers. - Double toggle jaw - Removed and dismantled - In storage - Bare jaw, no motor - A1 type machine - Feed opening: 42 x 48 inches - Throughput: 290-475 TPH - Closed side setting: 15-25 cm - 150-175 HP motor required. USA.

Jaw Crushers for sale

Whether you're just getting into the business of mining or are looking for an upgrade, a jaw crusher is an industry must-have. Designed for crushing rock to

how big can a jaw crusher crush a rock

The jaw rock crusher has simple structure, convenient operation, stable working condition and low operation cost. The quarry crushing machine's crushing ratio is large and the crushing strength is uniform. The discharge port can be adjusted, so it can meet the needs of different customers. PE1500 1800jaw crusher.

CDI C60 PTO Crusher - Jaws Mini Crushers

Heavy Duty Jaw Crusher with an Hydraulically adjustable CSS to suit required output size. Its on-board conveyor stockpiles crushed material and folds for transport. All components are driven direct from a standard 50hp to 90hp Tractor. It can be fed from a Conveyor or directly from a Digger.

Rock crusher HUGE rock!

Extec C12 eats a 1000kg huge rock

What are the Materials of the Jaw Crusher Plates and Which is Better

The structure of the jaw crusher is mainly composed of a movable Jaw Crusher Plates, a fixed jaw plate and an eccentric shaft. When the eccentric shaft rotates, the movable jaw plate mainly bears the squeezing action of the material, and the fixed jaw plate mainly bears the sliding cutting action of the material.

+86-21-63353309

+86-21-63353309

Leave a Comment