double roll crusher working principle

Roll crusher working principle | Henan Deya Machinery Co., Ltd

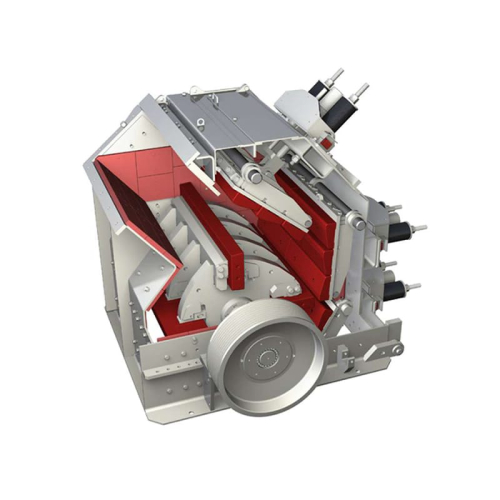

20/08/ · A. Double Roll Crusher. Double roll crusher is a commonly used roll crusher, whose structure is detailed in Figure 1. Its crushing mechanism is a pair of cylindrical rolls mounted

Advantages and Disadvantages of Roll Crusher

The roller crusher, also known as double roller crusher , is suitable for medium and fine crushing. Its main component is toothed roll.

Working Principle Of Smooth Roll Crusher Compression

Double roller crusher working Principles: Click & Chat Now. roller crushing working – CGM Project Case. Working Principle of Roll Crushers: A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. Click & Chat Now. building up roll crushers – beltconveyers.net.

Working Principle Of Smooth Roll Crushers - Stone Crushing

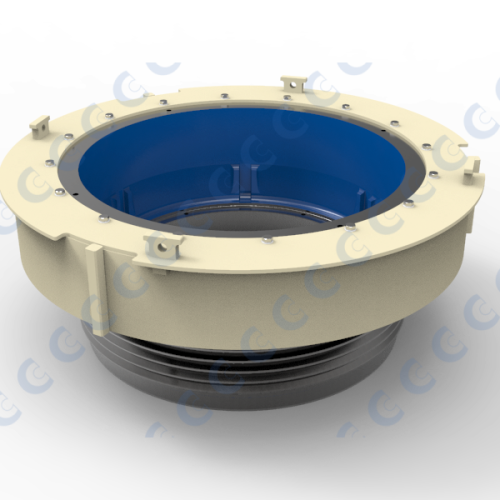

Roll crusher,Roller crusher,Double roll crusher,Teeth roll crusher Structure and Working Principle of Roll Crusher : 1. This series of roll crusher is composed by several parts of roll wheel, roll wheel axial bearing,

Roll crusher,Hydraulic double-roll crusher,Cone crusher For

Working principle and structure · 1. This series of roller crushers are mainly composed of rollers, roller supporting bearings, pressing and adjusting devices,

Double Roll Crusher Design Principles

Roll Crusher Construction Operating Principle. Local Rule 47.5 provides The publication of opinions that have no on the basis of wellsettled principles of law imposes needless expense on the public Twin Roll Crusher which it sold to Mallette Brothers in 1974.The Roll Crusher was the crushers control mechanism was constructed adjacent to the roll crusher.The crusher began operation in late 1974

Roll Crusher Working Principle

Roll crusher working principle roll crushers, or crushing rolls, or double roller crushers, are still used in some mills, although they have been replaced in most installations by cone crushers. they still haveseful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum, phosphate.

Roll Crusher Working Principle

working principle of crushers Roll crushers - SlideShare. Apr 24, DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two

Double Roll Crusher Working Principle-HN Mining Machinery Manufacturer

Aug 11, The Working Principle of Roll Crusher. Double-roll crusher can be divided into high speed and low speed double-roll crusher according to the revolving speed of roller; According to the installation methods of roller, it can be divided into two kinds: a roller bearing is active, and the other bearings is fixed and two roller bearings are active

Smooth Roll Crusher - J.C Steele & Sons

Crushing and shearing play a critical roll in mix quality, so we use a twin-speed roller design. The slow roller turns at approximately 280 rpm and is paired

double roll crusher lay out

Double Roll Crushers. Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals

+86-21-63353309

+86-21-63353309

Leave a Comment