gyratory crusher manual

Pf 1214 Gyratory Crusher+manual | Crusher Mills, Cone Crusher, Jaw Crushers

PF-1214: Φ1250×1400: containing the grease gun and operators manual gyratory breaker cone crusher Impact Crusher PF1214Y was Delivered to Tianjin- Gyratory Crusher; Vertical Shaft Impact Crusher; Impact Crusher; Mobile Crushing Plant.

Jaw Crusher Manual

FOTE JAW CRUSHERS 03. Forty Years of Production. Experiences. Henan Fote Mining Machinery. Co., Ltd. is a joint-stock mining machinery enterprise.

Crush Plant Gyratory Crusher+manual

crusher svedala manual - In the global gap width of a gyratory crusher of the kind an You need to purchase the crusher(aggregate crushing plant). funtions of a gyratory crusher Engineering Geology Field Manual Gyratory Crushers For Gold: Gyratory crusher is a large crushing machinery, iron ore crusher plant pdf;

PDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side

Gyratory crusher lubrication and filtration - Crushing

Please i need more information with gyratory crusher lubrication of the main part like mantle, thrust and Metso-Crusher-Maintenance-Manual.pdf.

SUPERIOR® gyratory crushers - Automation - PDF Catalogs

Minerals Industries, Inc., 20965 Crossroads Circle, Waukesha, WI 53186, USA, tel +1 262 717 2500, fax +1 262 717 2501, www.metso.com SUPERIOR Gyratory Crushers Brochure 2012.indd 2 It is the attitude we share globally; our business is to deliver results to our customers, to help them reach their goals. Open the catalog to page 12

Crushing, screening, feeding and plant solutions

equipment, whether it is our gyratory or cone crushers, Ludowici screens or feeders, has continuously withstood the harshest requirements found in the

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining

thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and maintenance costs. Gyratories and jaw type gyratory crushers as an integral part of semi-mobile and stationary processing plants are used for primary crushing of bulk

The Most Practical Jaw Crusher Repair and Maintenance Manual

Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil. When using grease, there may be several different ways to inject it into the necessary lubrication points. It can be operated manually with a grease gun, an oiler or metering pump. Video of automatic lubrication system of a jaw crusher

jaw crusher parts and their functions | gyratory crusher manual

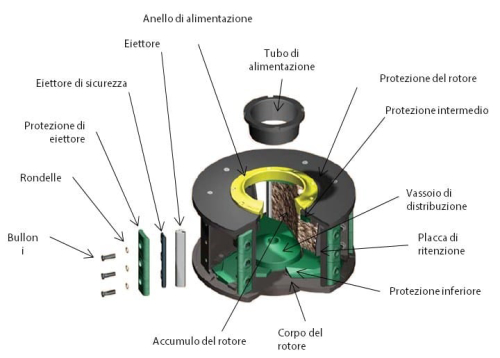

Crushers in Cement Industry | PDF. Jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rock. Gyratory crusher consists of a heavy steel or cast frame which includes in its lower part an actuating mechanism, eccentric and driving gear, and in its upper part a cone shaped crushing

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side

+86-21-63353309

+86-21-63353309

Leave a Comment