vibrating grizzly feeders

Vibrating Grizzly Feeder: Finger-Screen™ | General Kinematics

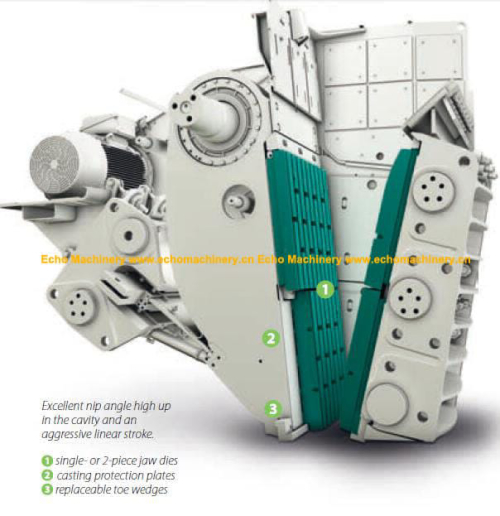

Improve your efficiency and lower your maintenance needs with General Kinematics. The FINGER-SCREEN™ Grizzly Screen provides a pan component at the feeder that begins to separate the material. Mounted on springs, the feeder is vibrated, causing the material to move along and be sifted as it moves toward the discharge end.

Vibrating Grizzly Feeders | McLanahan

Vibrating Grizzly Feeders are engineered to combine the functions of feeding and scalping into one unit, reducing the cost of having two separate units.

Simplicity GF Series Vibrating Grizzly Feeders - MPS

Standard grizzly feeder sizes range from 39" x 10' (990mm x 3048mm) to 86" x 30' (2184mm x 9144mm). The grizzly feeder reduces maintenance and capital costs by scalping only large material to your crusher or rip rap pile, while fines pass through the grizzlies to be screened or discarded.

Intrepid® Vibrating Grizzly Feeder | VGF | Superior Industries

Intrepid Vibrating Grizzly Feeders are made up of a pan section on one end followed by a series of evenly spaced steel bars at the other. Material is fed to the pan — usually by a loader — and carried across by a vibrating force. The vibration also helps move finer particles to the bottom of the load.

ELRUS Grizzly Bars and Feeders

Vibrating grizzly feeders remove fine material from crusher feed before it enters the jaw. No contamination within the crushing chamber promotes rock on rock

Vibrating Grizzly Feeders Market Size, Global Forecast to 2028

Report Summary. Eternity Insights has published a new study on Global Vibrating Grizzly Feeders Market focusing on key segments as by Type (Type 1, Type 2, Type 3, Type 4, Type 5), by Application (Application 1, Application 2, Application 3, Application 4, Application 5,), and by region.This deep dive re-search report highlights the market and competitive intelligence

What are the common problems with vibrating feeders and how to solve

The vibrating feeder can also be a vibrating feeder. The vibrating feeder is an indispensable equipment in the crushing sand production operation. In the production process, it can uniformly remove the block and granular materials from the storage bin. It is fed to the receiving device regularly and continuously. In the sand and gravel production line, the crushing machine can be fed

Vibrating Grizzly Feeders - Agremine

Range of Vibrating Grizzly Feeders with out grizzly bar sections removes fines, boosting degrees of isolation of vibration from the superstructure.

Vibrating Grizzly Feeders - EarthWORKS Machinery Company

EarthWORKS Machinery Company Feeders Vibrating Grizzly Feeders Showing all 2 results 2002 – Deister 48” wide x 16’ long Vibrating Grizzly Feeder $ 64,900.00 Crusher Trailer – Portable Three Axle Jaw Crusher Trailer with Vibrating Grizzly Feeder & Hopper $ 35,000.00

Vibrating Grizzly Feeder Advantage Series

The Cedarapids Advantage Series vibrating grizzly feeder (VGF) provides high production and long service life in a wide range of rigorous applications. The feeder design allows for better crushing equipment utilization. The large stroke produces high throughput tonnage with superior material separation at the grizzly. You get

Hillsboro, OR - Grizzly For Sale - Yamaha ATVs - ATV Trader

Yamaha Grizzly ATVs For Sale in Hillsboro, OR - Browse 36 Yamaha Grizzly ATVs Near You available on ATV Trader.

+86-21-63353309

+86-21-63353309

Leave a Comment