hydraulic wear rings

Guide Rings & Wear Rings for Hydraulic Applications

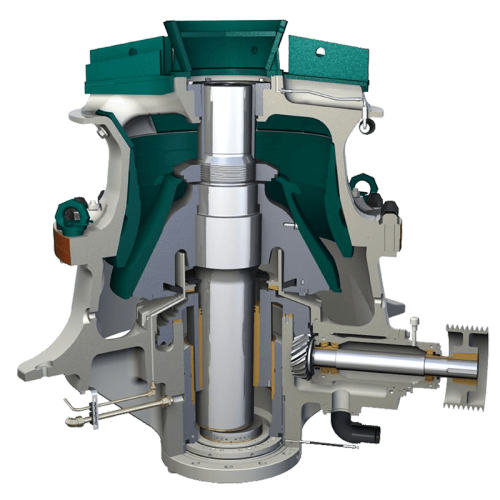

The guide ring or wear ring guides a hydraulic cylinder piston and rod and absorbs lateral forces. Metal to metal contact between the moving parts of the

Consider Wear-Ring Options - Efficient Plant

9/21 · Thermoplastic wear rings are the workhorses of hydraulic systems. In many systems, they are temperature resistant and can provide a high level of performance at a more affordable price than PTFE-based or thermoset wear rings. Most can be mated with steel, hard chrome-plated surfaces, and cast iron. Internal valves and compressor components are

PDF Precision Close Tolerance Wear Guides - Hi-Tech Seals Inc.PDF

Macrotech Polyseal Wear Guides replace metallicbearings in hydraulic cylinders and otherapplications providing a contact surface forreciprocating cylinder rods and pistons - reducingthe cost of the metal components. When wearguides are used, metal components can beproduced from low cost materials that may not besuitable for bearing service. Sin

Wear Rings - Columbia Industrial Products

CIP SELF-LUBRICATING COMPOSITE WEAR RINGS CIP custom wear rings are a superior alternative to commonly used cotton phenolic and glass filled nylon materials. They allow smooth operation and high side loads while protecting the sealing elements and preventing metal to metal contact in hydraulic cylinders. CIP wear rings are preferred where high performance, large

Wear Ring Supplier - Hydraulic Wear Rings | Rocket Seals, Inc

Wear rings guide pistons and piston rods in a hydraulic cylinder, minimizing transverse forces and preventing metal-to-metal contact. Use of wear rings reduces friction and optimizes the performance of piston and rod seals. We supply standard and metric wear ring material used to manufacture wear rings to meet your application requirements.

Material matters: Understanding wear ring benefits

At their most basic, wear rings absorb the side load forces in a piston and/or rod hydraulic cylinder, while eliminating metal-to-metal contact.

Trelleborg Hydraulic Wear Rings - Daemar Inc

Hydraulic Wear Rings. Slydring® is the Trelleborg Sealing Solutions proprietary design of hydraulic wear ring or guide ring. The function of a hydraulic wear ring is to guide the piston and piston rod of a hydraulic cylinder, absor transverse forces. At the same time, it prevents metal-to-metal contact, optimizing the performance of the

Wear Rings | Dynamic Seal | American High Performance

Our non-metallic wear rings for rod and piston applications offer great benefits over traditional metal guides: High load bearing capabilities. Cost effective. Easy installation and replacement.

Wear Rings | Zatkoff

WN commercial wear rings can be used for either pistons or rods and are the most economical bearing solution for light- to medium-duty hydraulic applications, Filled PTFE Wear Ring Bearings, Filled PTFE bearings are used to guide pistons and rods in cylinders and to provide good radial loading capacity (15 N/mm2 max dynamic).

Wear Rings and Strip - Sealing Australia

Wear rings, aka guide rings, bearing rings etc; distribute load evenly and avoid metal to metal contact in hydraulic and pneumatic systems.

Wear Rings - O Rings Limited

The function of hydraulic wear rings is to guide the piston and piston rod of a hydraulic cylinder. They absorb transverse forces while at the same time

+86-21-63353309

+86-21-63353309

Leave a Comment