sag mill operation

Model Predictive Control for SAG Milling in Minerals Processing

SAG and ball mills are generally accepted as the largest power consumers in a mining and mineral processing operation and.

Optimizing your SAG mill operation - International Mining

2007/3/21 · • Allow the mill to operate at maximum capacity • Ensure good grinding conditions with lower grinding energy per tonne • Efficient operation even at higher mill

What's the Difference Between SAG Mill and Ball Mill

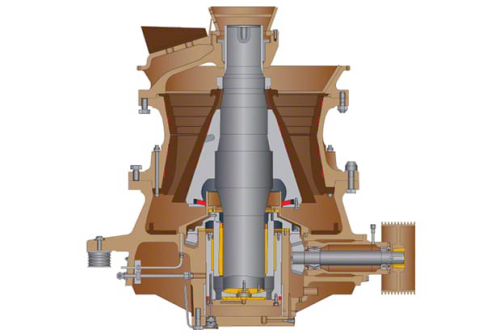

The working principle of the self-grinding machine is basically the same as the ball mill, the biggest difference is that the sag grinding

PDF EXPERIENCES IN SAG MILL OPERATION - intermetperu.comPDF

Describe in detail SAG mill circuits of large-scale plants and the benefits of each. - Detail the issues occurred during SAG mill operation: blockage of grates, cracking of bolts, liners and grates, flowback, carry over; blockage and breakage of meshes from trommel and screen, among other relevant issues.

SAG Mill Grinding Circuit Design - Mineral Processing & Metallurgy

SAG mill operation is more dynamic, and typically requires a higher degree of process control sophistication. Though more complex in AG/ SAG circuits relative to the crushing plants they have largely replaced, these issues are well understood in contemporary applications.

Influence of feed size on AG / SAG mill performance

2001/1/1 · However, as exemplified in this paper, the Strategic and Tactical Mine-to-Mill aims at real-time re-scale of mining and processing activities for optimal outcomes in response to large uncertainties

degrussa milling circuit - critical issues, modifications and results

Option 1, a jaw crusher followed by a SAG mill and a ball mill was considered the best combination of capital cost, operating cost, ease of operation and

Operation Of Sag Mill

operation of SAG mills. SAG mills are currently the technology of choice in hard rock milling operations for reducing primary-crushed ore to ball mill feed. In recent years, the trend has been towards larger-sized SAG mills with diameters of 10.4 m 34 ft and above, with the largest being 12.2 m 40 ft in

SAG Mill Process Control - Grinding & Classification Circuits

The purpose of a grinding mill is to convert electrical energy into rock breakage. The best use of that asset is to try to maximize the power draw. Try to hold the mill speed high and vary the feed rate to hold the weight (or bearing pressure), but watch out for "cycling" or "surging" that indicates instability in the charge.

SAG mill Optimisation and increasing throughput at the Phu Kham Copper-Gold Operation

8/30 · Mill Operators SAG mill Optimisation and increasing throughput at the Phu Kham Copper-Gold Operation – a success story This product is exclusive to Digital library subscription Subscribe SAG mill Optimisation and increasing

SAG MILLING IN AUSTRALIA – FOCUS ON THE FUTURE

The drive for low operating cost has seen the retention of fully autogenous circuits in some large installations, notably Olympic Dam. ISSUES IN MILL AND

+86-21-63353309

+86-21-63353309

Leave a Comment