sandvik 3r12

Spring Steels :: Total Materia Article

On the other hand 's spring steels cover most requirements for the materials properties. 3R12, S30403, 304L, 1.4306, 600-1300.

3R12 - Materials Technology - PDF Catalogs | Technical

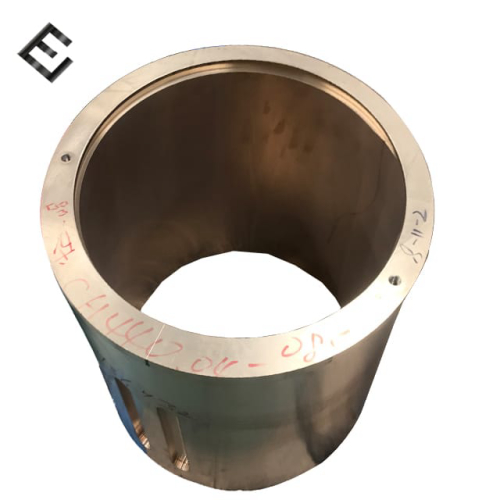

3R12 (Tube and pipe, seamless) 3R12 is an austenitic stainless chromiumnickel steel with a low carbon content. STANDARDS Product standards Approval JIS approval for Stainless Steel Tubes CHEMICAL COMPOSITION (NOMINAL) % C Subject to agreement, material with extra low Co content can be supplied.

3R12 - PDF Catalogs | Technical Documentation

3R12 (Tube and pipe, seamless) 3R12 is an austenitic stainless chromiumnickel steel with a low carbon content.

Welding of Gas-Tight Pipe Walls Made of Composite Pipes of

The outer part of the composite pipe is made of 3R12 steel (grade ASME 304L/SA) and has austenitic microstructure, whereas the inner pipe – of

pipe – tube – bar - MONILEK Oilfield Group

3R60 with OD above 42 mm. OD +/-0.50%, but min +/-0.1 mm (D4), WT +/-10%, but min +/-0.2 mm (T3). Standards. 3R12 (TP 304/304L) and.

Stainless tubular products stock program

4) ASME B31.3 at 40 °C. Max. allowed stress for 3R12 = ASTM TP 304 and for 3R60 = ASTM TP 316. Calculated wall thickness tolerance -10%.

Stainless tube and pipe — Alleima - Materials Technology

H-Q. Heat exchanger tubes. High-pressure tubes. High-temperature tubes. Hollow bar. Hydraulic and instrumentation tubing. ISO/EN tubes. Lance tubes. Laying head pipe.

pipe – tube – bar - Rectus

mm (T ). Standards. 3R12 (TP 304L) and. 3R60 (TP 316L). DIN 17458,

Construction Equipment For Sale in HILLSBORO, OREGON - 4

Browse a wide selection of new and used Construction Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include QA340, QE341, QI340, and UI310

Unit Import Data in June

smls ss pipes,tp304/304l 3r12, asme sa312, [qty:30.94mtr x unit price:174.40usd][tst-e-3r12-6-sch40]en 1.4306/1.

Sanmac® 316/316L — Alleima - Materials Technology

2022/5/10 · Sanmac ® 316/316L can be used in. Air up to 850°C (1560°F) Steam up to 750°C (1380°F) Creep behavior should also be taken into account when using the steel in the creep range. In flue gases containing sulphur, corrosion resistance is reduced. In such environments, the steel can be used at temperatures up to 600–750°C (1110–1380°F

+86-21-63353309

+86-21-63353309

Leave a Comment