crusher backing

Crusher Backing - Nordbak

PART NO. PRODUCT, DESCRIPTION. 9505 9910 (10 kg), PRIMARY BACKING, NORDBAK® PRIMARY BACKING for backing metal wear plates in Primary Gyratory Crushers

Crusher Backing Materials Market | Global Industry Report, 2030

The crusher backing materials market is slated to expand at a modest CAGR of ~4% during the assessment period. This is evident since certain companies are developing crushers and grinding mills that do not need crusher backing materials. This may affect revenue sales of crusher backing materials, thus lowering revenue collection.

HPZ Crusher Backing

Crusher backing for all makes of rock crushers, along with hydraulic clamping and adjustments system for cone crushers.

North America - Crusher repair products - Henkel Adhesives

LOCTITE® PC 9020 (known as NORTH AMERICA - NORDBAK HP CRUSHER BACKING) is a blue, 2-part epoxy system for backing wear metal in gyratory and cone crushers under typical dry

LOCTITE PC 9020 NORDBAK HP CRUSHER BACKING 10KG - Maith Gulf

known as NORTH AMERICA - NORDBAK HP CRUSHER BACKING, is a 2-part epoxy system for backing wear metal. LOCTITE® PC 9020 (known as NORTH AMERICA - NORDBAK HP CRUSHER BACKING) is a blue, 2-part epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of -20 °F to +220 °F (-30 °C to +105 °C).

PDF LOCTITE Nordbak Crusher Backing Materials - Kaman Industrial TechnologiesPDF

Standard Mixing Instructions 1. Pre-mix resin for approximately one minute. 2. Prior to opening hardener, shake container thoroughly, mixing the contents. 3. While mixing resin, add hardener contents to resin container. 4. Mix both components together, as directed on the Technical Data Sheet.

Crusher Backing Compound - IndiaMART

Crusher Backing Compound - High-strength liquid epoxy with the necessary resiliency and strength to withstand forces generated by crushers and mills for

Megapoxy Crusher Backing I Mining Wear Parts

Crusher backing is used to secure internal crusher parts to minimise vibration, friction, and impact to the equipment during crushing and operation.

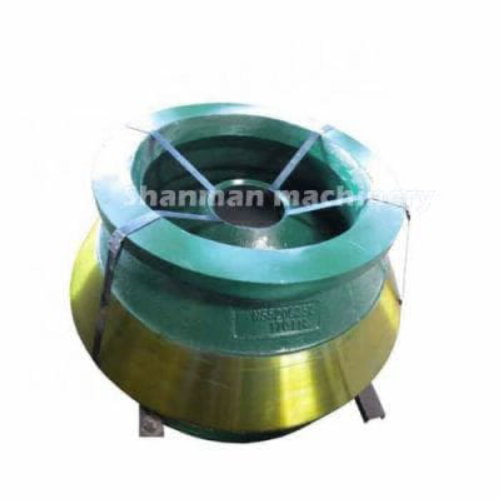

HP Crusher Parts Mantle Filler Crushing Backing Compound

HP Crusher Parts Mantle Filler Crushing Backing Compound Apply To Metso. Hyton (Jiangsu) supply the one-stop service for almost all the spare and

301 High Impact Crusher Backing | Polygem Epoxy

301 High-Impact Crusher Backing is 100% solids epoxy resin system. It is a safe, convenient and economical way to back metal surfaces in all types of crushers and grinding mills.

Crusher Backing Compound - Crusher Backing

Pouring: After mixing evenly, pour immediately. Pour at one place and allow backing material to fill the cavity and push out the air in front of it. Use dam (tin, cardboard or clay, etc.) to direct the flow when necessary, until full. Unmixed resin (different color clinging to the sides and bottom) should not be drained into the crusher.

+86-21-63353309

+86-21-63353309

Leave a Comment