vibrating grizzly feeder design

Vibrating Feeders for Conveying and Dosing • NetterVibration

We have developed vibrating feeders and dosing systems that provide solutions for a wide range of industries and Whatever your product and application may be, we design a totally customized feeder adapted to your needs. Netter Fritz-Lenges-Straße 3 55252 Mainz-Kastel +49 6134 2901-0 info(at)NetterVibration.com. Legal Notice

OEM manufacturer Vibrating Grizzly Feeder Design - ZFK Type Vibrating

Vibrating Mining Equipment Feature & Advantage Applications Service conditions: Requirements of Vibrating Feeder Machine for environmental conditions are as follows: 1. The ambient temperature is no more than +40℃; 2. Air relative humidity is no more than 90%; 3. It can be use

VIBRATING, GRIZZLY & PAN FEEDER Manufacturer & Supplier from Dhansura

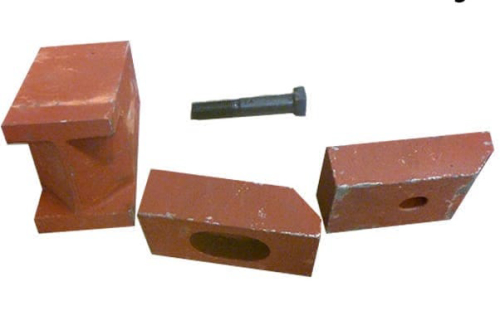

The Grizzly vibro feeder consists of a very large vibrating body made of thick plate, with inside lining of anti-abrasive plate. The Grizzly vibro feeder is driven by two vibrating motors or eccentric shaft. Salient Features: - Special design of grizzly bars eliminates material clogging and to better sizing effect

Vibrating Grizzly Feeders | McLanahan

Why McLanahan Vibrating Grizzly Feeders. The McLanahan Vibrating Grizzly Feeder has a history of reliability and durability. McLanahan offers feeders in five different widths to match up to

Grizzly with vibrating feeder - GrabCAD

2013. 8. 1. · Grizzly with vibrating feeder. Riaan. August 1st, 2013. One of the most common types of equipment used within the mining and quarrying industries. LHD / dump truck or

Vibrating Grizzly Feeder - CPC Crushing and Screening Equipment

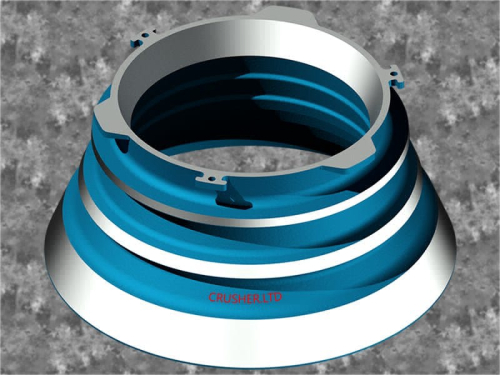

Vibrating Grizzly Feeder. Feed Capacity. The capacity of vibrating grizzly feeders is calculated according to the following formula: Q=3600 x f1 x f2 x f3 x L x H x V. where, Q=Feed Capacity in (m3/hr) To obtain capacity in Tons per Hour, multiply by bulk density of the material. Qt = Q x bd bd = 1.6 Tons/m3 for sand and crushed stone; f1 is

Vibrating Grizzly Feeder Advantage Series - Corporation

2020. 11. 10. · The adjustable bolt-together grizzly section provides for optimum “fit” between grizzly side sheets and feeder frame. The rear grizzly bar support is bolted directly into the pan support for added strength and rigidity. The VGF design is available with a 60” (1524 mm) grizzly section in a flat or sloped arrangement. The 20’ (6.1 m)

Vibrating Grizzly Feeders | Classification & Separation | DOVE

DOVE Vibrating Grizzly designed for Low noise, Low Power consumption, Steady vibration, Continuous and uniform feeding, large feeding capacity, and adjustable grid spacing. DOVE Vibrating Grizzly is configured with abrasion resistant Grizzly Bars, abrasion resistant Lined Bed and Side Plates, and adjustable & replicable Grizzly Bars. APPLICATIONS:

Vibrating Grizzly Feeder Design Manufacture and Vibrating Grizzly

Vibrating Grizzly Feeder Design - manufacturer, factory, supplier from China. Large Capacity Used Small Rotary Vibrating Grizzly Feeder. Low Running Cost Electromagnetic Vibrating Feeder. Small Volume Electromagnetic Vibration Feeder. River Stone Rigid Structure Vibrating Feeder.

Pan Feeders - Astec

Astec pan feeders are mechanically driven with a heavy-duty formed deck and are designed to easily replace competitive models. These feeders feature support springs with guards, bolt-in replaceable liners, re-greaseable bearings and exposed exciters for ease-of-access. Additional options include cone discharge spout, rubber liners and variable

vibrating grizzly feeder design China Manufacture, Exporter, Supplier

vibrating grizzly feeder design We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for vibrating grizzly feeder design Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of

+86-21-63353309

+86-21-63353309

Leave a Comment