lining crusher

Crushing - Outotec

The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety. Engineered spare and wear parts as well as maintenance and optimization services are designed with decades of experience in different crushers and crushing processes.

Crushing and grinding - Minerals - Weir Group

Tough and reliable crushing and grinding equipment. Designed to maximise performance and built for extra-long service life, our entire range of crushing and grinding equipment is backed by the Weir Minerals Service network, operating in over 70 countries across the globe. Find out more about our Enduron® HPGR.

Wear linings for crusher discharge vaults - Outotec

Traditional crusher discharge chutes, vaults and octagonals are a challenge to protect with wear liners and can be even more difficult to maintain and

How To Replace The Crusher Liner

How To Replace The Crusher Liner Replace the frame lining plate, such as old liner board can not get down, gas cutting, and the frame surface is clean. On the back of lining plate of new casting concrete, is 500 - 600, cement and sand, scale is at the mass ratio of 1:3 mixture.

Cone Crusher Liners | Crushing Wear Parts

We are a leading manufacturer and supplier of quality crusher liners and wear parts, customized for each application. Get in touch with us today to learn

RU2505359C2 - Lining for crusher with reduction gear-free motor drive

FIELD: machine building. SUBSTANCE: proposed lining comprises structural elements with bold bores. Bolt bores are arranged so that with structural elements located in crusher drum they facilitate and accelerate removal of lining elements without peripheral device. Peripheral device can be arranged at said drum and is composed of reduction gear-free motor drive engaged with crusher drum at the

Crusher lining board Manufacturers & Suppliers, China crusher lining

crusher lining board manufacturers/supplier, China crusher lining board manufacturer & factory list, find best price in Chinese crusher lining board manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

Cone Crusher Cavity Types And - Qiming Machinery

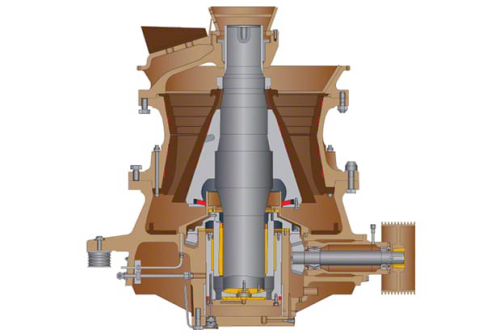

The most important factor in Cone Crusher liner selection is the feed. Cone Crusher Cavity Types. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as: 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two.

Cone Crusher Liners - Tempus Steel

Producing manganese crusher liners to best suit applications such as iron ore crushing, pebble crushing in gold/copper circuits, or crushing highly abrasive

Hammer Crusher Working for Cement Plant | AGICO CEMENT

This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining plate, grate screen, and shell. 1. Shell. The shell is composed of the lower body, the upper rear cover, the left and the right side walls.

lining crusher | sesh evo replacement earbud

How To Replace The Crusher Liner Replace the frame lining plate, such as old liner board can not get down, gas cutting, and the frame surface is clean. On the back of lining plate of new casting concrete, is 500 - 600, cement and sand, scale is at the mass ratio of 1:3 mixture.

+86-21-63353309

+86-21-63353309

Leave a Comment