hardox material

Hardox Wear Plate & Plate Fabrication | EMSCO

Hardox can extend the lifetime of machine parts and structures extensively, two to ten times compared to the competition. Also called AR, AR450, AR500, or armor plate, Hardox® is SSAB's flagship material, the industry standard for wear-resistant plating, and we are proud to be a certified supplier of this stellar alloy. Request a Quote

Re-Engineered Hardox Sprocket - Hardox Wearparts

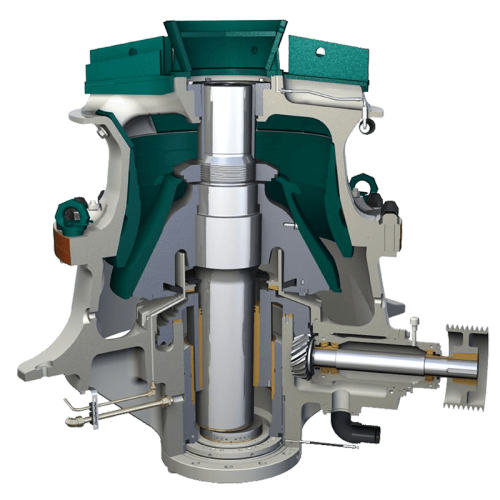

Customer approached us for a solution for severe damage of SPROCKET which is a wearing part of ROTARY SCREEN. Both Sliding wear and Impact wear acts simultaneously on the sprocket, so that we supplied HARDOX 500 SPROCKET with an improved design. We made two Design Changes, 1. Doubled the pitch as per the Chain size, So that we could make strong teeth. 2. Designed the Sprocket in 4 segments

HARDOX - HIGH STRENGTH WEAR RESISTANT STEEL

Hardox 600. Hardox 600 steel have high resistance, toughness and ductility to impact loads, retaining the ability to bond metal plates by conventional welding methods. This steel is referred to as the “high-quality abrasion-resistant steel”. Hardox 600 is intended only for application connected with an abrasive wear of base material and is

HARDOX-Material - Translation into English - Reverso

Translations in context of "HARDOX-Material" in German-English from Reverso Context: Wenn nicht anders gewünscht, verarbeiten wir original HARDOX-Material.

Hardox Steel Providers | MTL Advanced

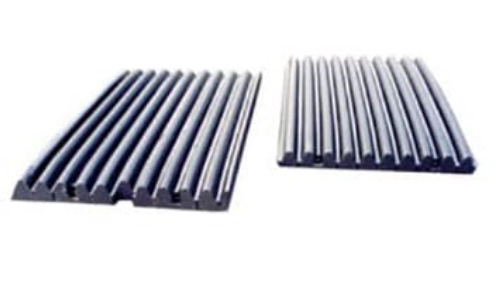

In products such as shredder blades, Hardox is proven to last twice as long as conventional steel, saving time, improving efficiency and reducing down-time. Due to our extensive manufacturing capabilities we can machine up to 700HB, press parts up to 7.2m in length and waterjet cut Hardox to avoid a Heat Affected Zone (HAZ).

Hardox - Mid City Steel | Steel Supplier- Rebar Fabrication - Steel

Only genuine Hardox ensures unbeatable performance, savings and enhanced lifetime for your equipment. Weather you are looking to loose weight or gain strength in applications such as truck bodies, dumper bodies, containers and buckets or if you need production wear parts that simply outlast other materials, Hardox is the best choice.

hardox 400 material hardness properties - Wear/Abrasion

The impact temperature is normal temperature, 0 ° C, -20. Iron and steel goods, including pig iron, ingots, all kinds of steel and so on. Therefore, logistics companies are required to load evenly and evenly in the process of transportation, prevent moisture and prevent corrosion. It is necessary to prevent the hardox 400 material hardness

Hardox steel: mechanical and chemical properties, scope, video tests

Hardox 500 steel has a fine grain structure. The table shows the maximum possible percentage of each element. Carbon, Silicium, Mangan, Chromium, Nichol, Molybdenum and Boron are alloying additives. Based on the components used, the carbon equivalent is calculated. The table shows the limit and average values for different sheet thicknesses.

Hardox 400 - Easy to form, wear-resistant steel from SSAB

Hardox® 400 is an abrasion-resistant steel with a nominal hardness of 400 HBW. Hardox® 400 is an all-around wear resistant steel. Thanks to its high toughness, good bendability and weldability, this steel can be used in structures with moderate wear. Order trial material Get free technical advice Bring it on Hardox® 450

Hardox 500 - Wear-resistant steel with extra-high toughness - SSAB

Hardox® 500 is a bendable and weldable abrasion-resistant steel, with a nominal hardness of 500 HBW. Suitable for applications that demand higher wear resistance. Hardox ® 500 increases

Hardox® wear plate- Wear and abrasion resistant steel - SSAB

Hardox® wear plate is the world's leading abrasion-resistant (AR) steel. Hardox® is hard through and through, from the surface deep. down to its core, giving you extended service life and high

+86-21-63353309

+86-21-63353309

Leave a Comment