loctite nordbak

PDF LOCTITE Nordbak Crusher Backing Materials - Kaman Industrial TechnologiesPDF

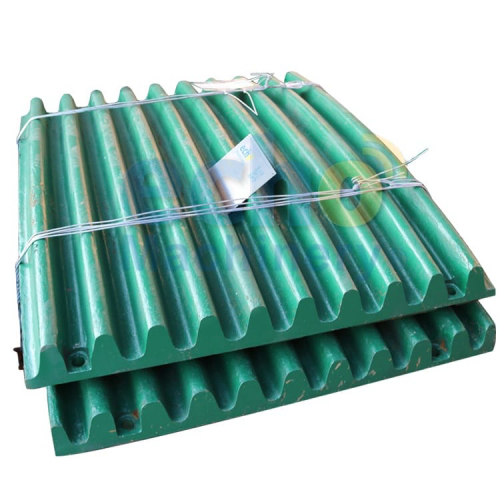

LOCTITE®Nordbak Backing Material • 100% solids epoxy compound for backing wear plates in cone crushers and grinding mills • Provides high compressive strength and impact resistance • High volumetric stability eliminates gaps between liners • Nonflammable • Pourable compound requires no melting or special equipment LOCTITE®Nordbak®Trowel Mix

Loctite® Nordbak® Wear Resistant Coatings - Krayden

Available in trowelable and brushable formulations with special fillers for tough conditions, Loctite® Nordbak® products stand up to almost any corrosion,

Henkel 96443 LOCTITE® PC 7228™ Nordbak® White Brushable ... - SkyGeek

Loctite® Nordbak® Brushable Ceramic White brushes on to form a smooth, corrosion-resistant coating. Protects against turbulence, abrasion, and cavitation. Can also be used as a top coat over Loctite Nordbak wearing compounds for surface rebuilding and lasting protection. Resists temperatures to 200°F.

LOCTITE Nordbak High Temperature Brushable Ceramic

LOCTITE® Nordbak® High Temperature Brushable Ceramic™ is an ultra smooth, ceramic reinforced epoxy that provides a high gloss, low friction coating designed

LOCTITE PC 9462 NORDBACK BACKING !! TIENDA LOCTITE !!

LOCTITE 9462 MATERIAL DE RESPALDO ANTIDESGASTE NORDBACK Compuesto de respaldo epoxico para proteger los trituradores, chancadoras y molinos. CARACTERISTICAS DEL PRODUCTO LOCTITE 9462 El material de respaldo LOCTITE Nordbak es un compuesto epoxi líquido de 2 partes !! ENVIOS TODO PERU !! 🥇🚚🛒🏪🛵

LOCTITE PC 7218 Nordbak® Wearing Compound - Henkel Adhesives

LOCTITE PC 7218 is a 2-part, grey, ceramic-filled, trowelable, epoxy-based surface coating for metals. Ideal for protecting against coarse particle abrasion or erosion, or for rebuilding worn parts. LOCTITE PC 7218 - 2-part, ceramic-filled epoxy surface coating - Henkel Adhesives Skip to content You have to accept the cookies to see this content

Current local time in Northlake, Illinois

Local Time in Northlake, IL. 8:37:27 PM, Sunday 10, July 2022 CDT 24 hours.

Nordbak Wear Resistant Coatings | Loctite, Fixmaster, Composites | John

Nordbak Wear Resistant Coatings Loctite® Nordbak® and Fixmaster® Composites REBUILD, REPAIR and PROTECT industrial equipment and surfaces, extending equipment life, improving efficiency and minimizing down time. With extremely hard reinforcement fillers, Henkel's polymer composite products have excellent wear resistance and superior adhesion.

LOCTITE PC 9593 Nordbak Wear Protection Coating - Henkel

LOCTITE® PC 9593 Nordbak® Wear Prevention Coating is an epoxy resin system designed to protect, rebuild and repair wear areas of processing equipment quickly, which is also subjected

Loctite Nordbak 7230 High Temperature Wearing Compound

Loctite® Nordbak® 7230 High Temperature Wearing Compound Ceramic filled two part epoxy to protect, rebuild and repair high wear areas.

LOCTITE PC 9020 NORDBAK HP CRUSHER BACKING 10KG - Maith Gulf

LOCTITE® PC 9020 (known as NORTH AMERICA - NORDBAK HP CRUSHER BACKING) is a blue, 2-part epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of -20 °F to +220 °F (-30 °C to +105 °C). The product eliminates the needs for traditional melting or special equipment and has high hydrolytic

+86-21-63353309

+86-21-63353309

Leave a Comment