tool balancing machine

Tool Dynamic Automatic Balancing Machine

9/11 · The TD Tool Dynamic Automatic is an automatic vertical CNC based balancing machine for tool holders on one and two planes for milling and drilling, offering the highest precision and

Balancing Machines | American Machinist

2007/6/21 · This includes the desired balancing tolerances in balance quality (optionally G or Q) and the specific density of material. Balancing operations of toolholders with a maximum weight to 33 lbs. and a maximum length to 13.5 in. (342.9 mm) can be done at speeds of 300 rpm to 1,100 rpm. Dimensional balance accuracy is less than 1 gram millimeter.

Tool balancing and RPM - Coromant

Tool balancing requirements · Machine tool spindles, clamping devices and tools are varying systems (e.g. by tool changes in machining centres) · Due to radial

Balancing Machine, Dynamic Balancing Machine - Nan Jung

there are all kinds of balancing machines, which including horizontal balancing machine, vertical balancing machine, soft type balancing machine, hard type balancing machine, dynamic balancing machine and static balancing machine that are all developed, designed and manufactured on our own, which may solve all kinds of vibration problem

Toolholder Balancing 101 | American Machinist

For these reasons, machine-tool spindles and machine-tool parts usually are specified with vibration levels of G2.5 and G6.3." G numbers generally are assigned to an overall assembly. A machine spindle assembly may have an overall design balance level of G6.3 in operation, while the spindle and the toolholders might be balanced to G2.5 Ievels.

Fundamentals of tool balancing - HAIMER

Fundamentals of balancing With rotating bodies, imbalance is an omnipresent phenomenon. A typical example are rotating tools on machine tools. Because unbalance creates a centrifugal

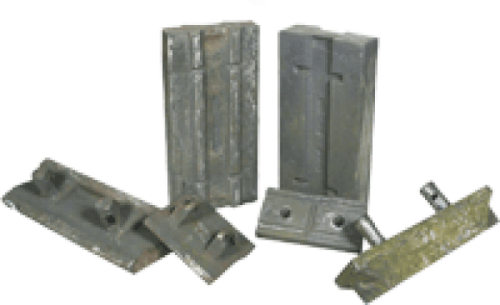

Katool Balancing Machine Use

The balancing machine is to carry out the dynamic balance comparison of the rotor in the rotating state. The functions of dynamic balance are: 1. Improve the quality of the rotor and its components; Reduce noise; 2. Reduce vibration. 3. Improve the service life of supporting parts (bearings). 4. Reduce the discomfort of users.

Balancing Machines - SCHENCK USA

Balancing Machines by Schenck 09/12/2022–09/17/2022 IMTS Location: McCormick Place - Chicago, IL Booth: 135246-SCHENCK USA CORP. | Booth: 432445-BENZ TOOLING a business unit of SCHENCK USA CORP.

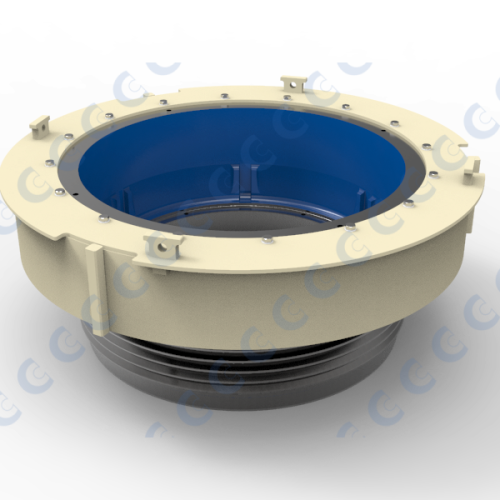

Toolholder And Tool Balancing Machines - Hines Industries

Toolholders and tools can be balanced quickly and precisely on the Hines Industries Model HVR-TB Toolholder Balancing Machine.

Balancing machine Tool Dynamic TD Automatic - Haimer

The Tool Dynamic TD Automatic is a truly universal CNC-based balancing machine with automated correction of the unbalance. It automatically compensates the unbalance in one or two planes by drilling or milling. The machine can work vertically and horizontally. The balancing machine is controlled by an integrated 19'' touchscreen.

Digital Demo: Precision Engineering Meets Digitization | Modern Machine

Since the beginning of the Industry 4.0 movement, Haimer has been an industry pioneer in digital connectivity between tools and machines. This forward thinking is reflected in their newest Industry 4.0 machine series. The wireless communication exchange helps to optimize and customize tool data for shrinking, balancing and presetting machine

+86-21-63353309

+86-21-63353309

Leave a Comment