Mill Liner

Rubber Mill Liners Market Analysis (2022-2028), Product Overview and

Global "Rubber Mill Liners Market" In the forecast period of 2022-2028 is expected to grow at a steady rate, according to the Rubber Mill Liners Market report, which summarizes the key aspects

Decision Support Models for the Maintenance and Design of

replacement policies for mill liners. Variation in the ore properties also affects the liner wear and ore value. Both these parameters have an effect on the

Raw Mill Liner for Cement - EB Castworld

Raw Mill Liner for Cement. Raw Mill Liners for Shot Blast Machines, Chutes, Clinker Silo,Port Machinery and Ball Mills. Shape: Flat Plate, Arc Plate, Waved Plates, Corrugated Plates. Bolted Plates: one-hole, two-holes, three holes, four holes, oval - hole.

The Selection and Design of Mill Liners - MillTraj

ABSTRACT. Dramatic shortcomings of mill liner designs, especially of large SAG mills, - such as rapid failure and even mill shell damage arising from

Mill Liner Market Size, Industry Share | Forecast, 2029

Mill liner is an equipment that protects the mill shell from wear & tear and transfers the energy to grinding charge. Primarily, a mill machine undergoes

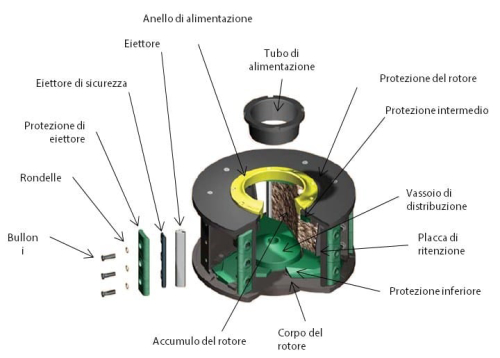

SAG and Ball Mill Liner - EB Castworld

SAG and Ball Mill Liner system serves two purposes: Protect the mill shell from wear caused by the impact and abrasion of the mill charge, and to elevate and tumble the mill contents in the necessary manner to create a grinding action. To achieve this, the mill liner profile must be constructed from high wear resistant materials and incorporate correct geometry to help determine the elevation

A Review on Current Mill Liner Design and Performance

Milling management in Mining and Mineral Industries should keep on improving liner design based on operating experience, ore types, good design practice,

Mill Lining Systems | FluidHandling - Trelleborg

Trelleborg has been providing mill lining systems since 1920. The focus is on working with our customers to provide incremental improvement to enhance mill

Ball Mill Liners - Polycorp

Rubber Mill Liners are chosen for most Primary, Secondary and Tertiary Ball Mills. In many cases rubber components are best suited for specific areas in AG and

Grinding Media, SAG Mill Liner, White Iron Mill Liner - H&G

110Г13Л high manganese steel ball mill liner ar Sep-18- 110Г13Л high manganese steel ball mill liner are ready for shipping H&G deliver 2 set High manganese steel mill liner Mn13Cr2 will be Sep-18- High manganese steel mill liner Mn13Cr2 will be sent to Russia H&G deliver 2 sets of high ma

Selection and design of mill liners - ResearchGate

Liners protect the mill shell from wear and transfer energy to the grinding charge. A careful balance is required to optimise these conflicting

+86-21-63353309

+86-21-63353309

Leave a Comment