crusher jaws

What are the Materials of the Jaw Crusher Plates and Which is

What are the jaw materials of the jaw crusher? High manganese steel. High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance.However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to

Trio® CT Series Jaw Crushers - The Weir Group

The Trio® CT Series jaw crusher is a robust comminution machine with innovative features that make it the clear choice for primary crushing applications within

CR 300 Crusher - Jaws Mini Crushers

EFFICIENT OUTPUT The CR300 Crusher's highly abrasive, resistant jaws and unique patent-pending crushing mechanism effortlessly crushes up to 6 tons of concrete an hour. With performance that is comparable to bigger crushers, its compact size makes it a more manageable and less daunting machine to use. TIME AND COST SAVING

Jaw crushers - SlideShare

30. Demerits: Jaw Crushers are very expensive crushing machines. The crushing action is intermittent due to which heavy foundations required. It is impossible to stop jaw crusher in emergency due to heavy flywheel. Restarting with choked machine is impossible. Flat shape particles can pass through jaws uncrushed.

Crusher Jaws Jaques Crushers

From primary jaw crushers to laboratory jaws, Jaques provide Posts Related to jacques 42 – 30 single toggle jaw crusher manual. jacques 3a hammer mill. Pe=250-400 Jaques

C80™ jaw crusher - Outotec

Compact ® C80™ jaw crusher is conventionally used as a primary crusher in small quarries, gravel pits, and small-scale mining operations.

Heavy Duty Jaw Crusher Latest Price ... - IndiaMART

The laboratory Aggregate Jaw Crusher is designed for fast crushing of aggregates, ores, minerals, coal, coke, chemicals and other similar materials. Its compact

CE AFRICA JAW CRUSHERS - New | Repairs & Spares

CE Africa | ME Series Jaw Crusher. Smaller closed side settings may be possible depending on application and end product requirements. The above figures represent through the crusher capacities, which are based on a feed material with an average specific gravity of 2.7 t/m3, a maximum feed size that will enter the crusher without bridging and material finer than the

Jaw crushers by SIEBTECHNIK TEMA. Crushing & milling

Jaw crushers are used for coarse grinding brittle, medium-hard to hard materials up to a Mohs' hardness of approx. 8.5. Here reduction ratios of up to 1:100

Jaw Crushers - Mt Baker Mining and Metals

Mt. Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials,

What is a Jaw Crusher? – MEKA Crushing Equipment

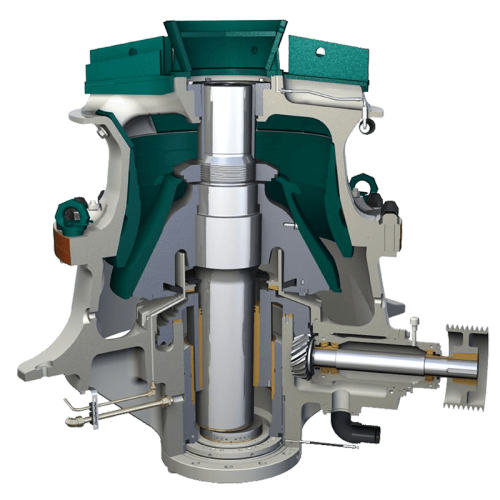

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that

+86-21-63353309

+86-21-63353309

Leave a Comment