apron feeder flights

Apron Feeder Flights Las piezas son... - Fundición Ferrosa

Apron Feeder Flights Las piezas son fabricadas bajo un estricto control de calidad para garantizar el encaje perfecto con la cadena y el giro de la

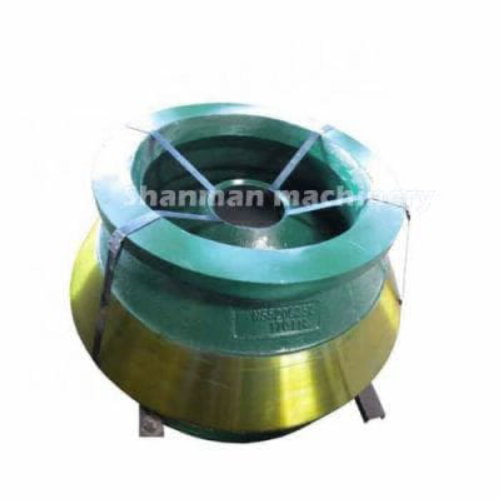

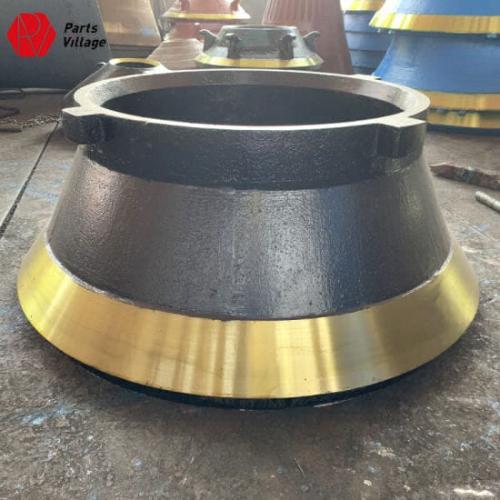

Apron Feeder Pans - Qiming Machinery

Apron feeder pans are the main wear parts in the apron feeder machine. Apron feeders are available in a wide variety of designs for both horizontal and inclined travel. They help in the feeding of material at controlled and continuous flow rates. These are mainly used to handle large-sized lumps.

Apron Feeder Flights, For Material Handling, Drives & Drives | ID

Drives & Drives - Offering Apron Feeder Flights, For Material Handling in Mumbai, Maharashtra. Get best price and read about company. Get contact details and address | ID: 25016037588

Apron Feeder High-strength, heavy-duty productive processing

Apron Feeders are ideal for a number of mineral process- ing applications, such as metals mining or quarrying, at the surface or underground.

Types of Feeders in Quarries | Quarrying & Aggregates

It is suitable for feeding jaw crushers and primary impact crushers. Grizzly feeder has a pre-screening function and can provide 1, 2, 3 and 4 bars to meet different application requirements. The opening of the grizzly bars can be adjusted within the range of 80mm-200mm. In Optional hanging screen layer, the screen hole is about 10-30mm, to

Tea Towel Apron TUTORIAL: Quick & Easy | TREASURIE

Pin Tea Towel Apron Folding Instructions. Step 4: Fold the 3 straps in half lengthwise with right sides together and stitch one end and along the length with a ½ inch seam allowance.The other end will be left open. Step 5: Clip the corners and turn the straps right way out. Give the straps a press. Step 6: Push the raw ends of the straps inside by ½ inch (12mm) and press.

Feeding the facts: Apron feeder basics - Outotec

Normally, the optimal speed an apron feeder is 0.05 - 0.40 m/second (10-80 fpm). If the ores are non-abrasive, the speed can increase to above 0.30 m/second because there will be less wear. Higher speeds would hurt an operation. If your speed is too high, you run the risk of accelerated wear of components. Energy efficiency decreases due to

Apron Feeder | Apron Feeder Manufacturer | Trimech India

05/25 · Trimech Manufacturers’ Apron feeders are constructed to serve the purpose of providing quality with a built that lasts longer to save you from heavy servicing costs and replacement. These feeders have supreme functionality and are made to sustain more stress and weight. Trimech Mfg specializes in supplying feeders that are tailor-made for

Success Stories: Universal Heavy-Duty Tractor-Chain Apron Feeder

Each Apron Feeder is custom-designed to optimize the overall performance of the system. With six chain sizes, 16 flight widths and an infinite range of lengths, these feeders are available in sizes to complement nearly any operation.

Flight for apron feeder - The Manufacturers Equipment Company

FIG. 1 is a reduced perspective view of a flight for apron feeder showing my new design; FIG. 2 is a top plan view thereof; FIG. 3 is a bottom plan view thereof; FIG. 4 is a front elevational view thereof, taken along the line 4--4 of FIG. 2; FIG. 5 is a rear elevational view thereof, taken along the line 5--5 of FIG. 2;

An expert insight into apron feeder evolution - Quarry Magazine

Machine designs have also evolved to improve operator safety. One such example, Thomas said, is the apron feeder pan, which is also referred to

+86-21-63353309

+86-21-63353309

Leave a Comment