material properties required in production of jaw crusher liners

Liner wear in jaw crushers | Request PDF - ResearchGate

Tests have been conducted to determine the wear coefficient in Archard's model. Using a small jaw crusher, the wear of the crusher liners has

Double Roller crusher parts_A professional concave

Its success is by quenching make the surface hardness of HRC50-55. Such roll skin can be used to check the fineness of the raw material hardness lower case and

Crushing and Screening Handbook - AusIMM

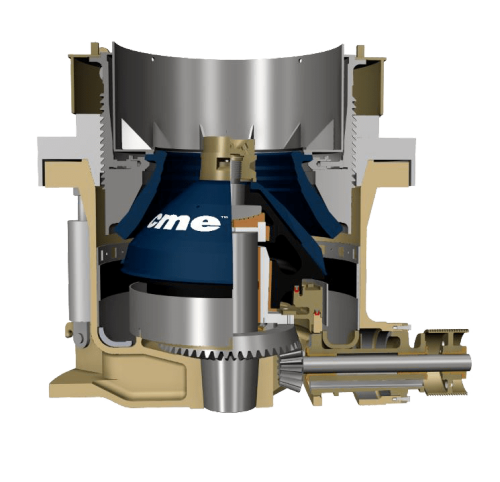

Its expertise covers the production of aggregates, the The VSI crushers with metal liners around RIOR gyratory crusher with features required by.

Rock crusher having crushing-enhancing inserts, method for

A jaw crusher incorporating replaceable manganese wear liners is disclosed, are requiring the production of gravel or other paving materials of

Principles of Extraction Material

The required metal is economical by known methods. physical properties of the ore. (toggle-plate), as some types of jaw crushers produce a.

Trio® CT Series Jaw Crushers - The Weir Group

Whereas, in the aggregates industry it is used to process a variety of materials including hard rock, sand, concrete, asphalt, slag, glass, limestone, lead and

Manufacturing and refurbishing of jaw crushers - RocketCDN

Horsepower requirements can vary from 75 hp to 400 hp. The entire crusher chamber is lined with replaceable 14070 manganese steel liner plates.

Jaw Crusher - an overview | ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral

Trio® crushers - The Weir Group

Manganese is a favoured alloy for those operating cone and jaw crushers due to the material's work-hardening properties.

Crushing, screening, feeding and plant solutions

This feature greatly simplifies safety procedures over more traditional/breakable toggle jaw crushers. Page 7. 7. Features. • 's bolted and pinned frame

Sand Aggregate Production Line for Soft Rock and Hard Rock

2022/9/14 · Three stages crushing and sand making process can be selected. Jaw crusher or gyratory crusher can be selected in the coarse crushing stage according to the material properties and production needs. After coarse crushing, it is sent

+86-21-63353309

+86-21-63353309

Leave a Comment