gyratory crusher mantle repair

gyratory crusher mantle repair | SPACER, INR LABYRINTH 1312

The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. The crusher is the workhorse of the hard rock crushing industry. A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves.

gyratory crusher mantle repair | HP200 SHIM 0,5 - Roll up Bydgoszcz

Horizontal Impact Crusher. Vertical Shaft Impactor; Screening. About Screening; Incline Screen Plants. 7'x20' 3-Deck Screen Plant; 6'x20' 3-Deck Screen Plant; MS612 High Capacity Multi-Slope Screen Plant; MS612 Feeder Screen; MS612 Twin Screen; 6'x20' 3-Deck Feeder Screen Plant; 6'x20' 2-Deck Scalping Screen; Horizontal Screens;

gyratory crusher mantle repair high manganese steel crusher

Gyratory Crushers - Mineral Processing & Metallurgy Feb 17, · Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a

gyratory crusher mantle repair | LWR CONCAVE MC M1 S4800

Applies to over 2200 products worldwide: • Available quickly and worldwide, including for the long term • Expected high Festo quality • Best value

Best 30 Home Repair in Hillsboro, OR with Reviews - YP.com - Yellow Pages

YEARS. WITH. (503) 681-8221. 2900 SE Tualatin Valley Hwy. Hillsboro, OR 97123. CLOSED NOW. From Business: Portland Materials Supply is conveniently located at 2900 SE Tualatin Valley Highway in Hillsboro, Oregon. Call us @ 505 681-8221 with questions on the products. 2.

gyratory crusher sales

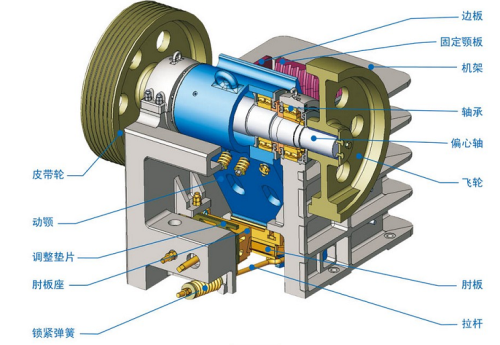

The gyratory crusher is composed of transmission, frame, eccentric sleeve, mantle, concave segments, middle frame, beam, prime mover, oil cylinder, hydraulic pressure, pulley, electrical and dry, thin oil lubrication, and other parts. The motor drives the eccentric sleeve to rotate through the belt pulley and the bevel gear, and when the

gyratory crusher mantle repair | building machine low price jaw crusher

Gyratory Crusher Mantle. The gyratory crusher mantle is the major wear part of the gyratory crusher. The mantle which is the movable working surface is pivoted at its top within a spider bearing under the cap of the spider arm assembly while the bottom is gyrated within an eccentric bushing which is powered by the drive assembly. AC 4265

gyratory crusher mantle repair | what are crusher main shaft step made of

PRIMARY MANTLE REPAIR One of Demitec's clients had a crack appear in the mantle of their primary crusher. The specialized repair required experience and expertise to asses the root cause and carry out a timely and sound repair. Demitec has been inspecting, overhauling and repairing gyratory crushers in vaious indutries for more than 25 years

gyratory crusher mantle repair | iso 8734 standard

Crushers (Rock Crushers) broadly categorized by jaw, roller, gyratory and cone crushers are the workhorse of the mining industry and are subject to extreme wear. The gyratory (primary) crushers and the cone crushers are comprised of a cast outer shell lined with wear plates, a treaded adjustment mechanism and an inner cone with a wear mantle.

gyratory crusher mantle repair | rf123g20 2020b

A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max. motor power Total weight of gyratory crusher

Kenmore Repair Hillsboro

Do you need Kenmore Repair in Hillsboro or in the surrounding areas? Call today and have one of our five star rated appliance repair professionals come out and service your appliance repair needs, CALL NOW 480-428-8129 REQUEST CALLBACK BOOK ONLINE. TO ORDER PARTS 877-298-2785 Same Day Shipping. Toggle navigation. About Us;

+86-21-63353309

+86-21-63353309

Leave a Comment