what is an apron feeder

apron feeder osborn

Apron Feeder Apron Ituhs. osborn range introduction to apron feeders type widths capacities tph d4 900 2100 mm up to 1500 d6 1200 2400 mm up to 2000 d7 1500 3000 mm up to 2500 d8 1500 3000 mm up to 2500 d9 2000 apron feeder,vibrating feeder,apron feeders our apron feeder also has an integral matching scraper conveyor with built-in drive to

Apron feeders: the material handling workhorses

In simple terms, an apron feeder (also known as a pan feeder) is a mechanical type of feeder used in material handing operations to transfer (

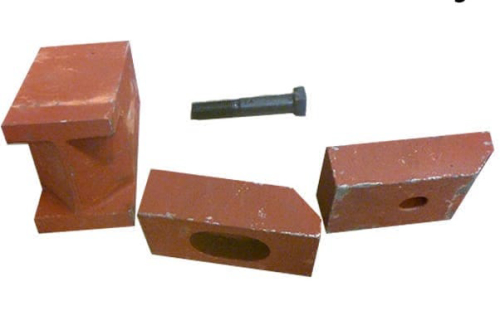

Apron Feeder Pans - Tempus Steel

Apron Feeders are commonly used for controlled feed hopper discharge to primary crushing plants and are, therefore, critical assets in the production process. The impact from ROM material directly dumped onto the apron feeder can be extreme and the manufacturing integrity of the apron feeder and the apron feeder pans is paramount.

Apron feeders | manufactor | thyssenkrupp Mining Technologies

The drive system of apron feeders is of special importance because it must be able to start the conveyor under full load and ensure a uniform

Reliability centered maintenance: apron feeders | Assetivity

Reliability Improvement. ->. Reliability Centered Maintenance (RCM) in action: apron feeders. In mining operations, apron feeders are generally located under RoM bins or underground in a dusty, hot or wet tunnel fed from a RoM stockpile, and are typically used to provide the means of moving coarse material when it first enters a processing plant.

US6662930B2 - Apron weigh feeder - Google Patents

An apron weigh feeder for use in the heavy bulk materials industry includes a feeder frame, a head drive shaft, a pair of tail traction wheels, and a plurality of carry and return rollers. A pair of drive sprockets is mounted on the head drive shaft. The tail traction wheels

Analysis and calculation of chain tension of apron feederss for mineral

Apron feeders is one of the feeding equipment in material crushing system, divided into heavy duty, medium duty and light duty, and now the common one is heavy duty. Heavy apron feeders is suitable for short distance conveying materials with large capacity and particle size, also can be used as a buffer bin to feed the primary crusher, can continuously and evenly feed the next process, can

Steel Apron Feeders - ATMOS Handling

atmos is a recognized specialist for proof steel apron feeders / extractors. Our steel apron feeders are proven effective for the extraction of difficult

MAF SERIES APRON FEEDERS

MEKA Apron Feeders are installed in horizontal as well as in inclined applications. Due to the special design of the aprons an inclination range up to 15 can be realized. In ad-dition the bed height of the conveyed material stays con-stant ensuring an equal

What is the difference between Belt and Apron Feeders?

Apron fed machines often cost about $20,000 more than their belt fed counterparts. Belt feeders on the other hand are much better for secondary applications where smaller aggregates that will not be dropped from height are to be considered. They can move material over longer distances much more efficiently however come with the added cost of

What is Apron Feeder

Apron feeder is widely used in mining, concentrator, chemical, cement, building materials and other industries, widely used in the storage bin to crushing, transportation and other machinery for uniform continuous feeding. The head and tail bearings are equipped with rolling bearings. The head bearing seat is not supported on the frame

+86-21-63353309

+86-21-63353309

Leave a Comment