cement cooler

Grate Cooler - INFINITY FOR CEMENT EQUIPMENT

2.2 Reciprocating Grate cooler · It have been used for years as an effective means for clinker cooling · The basic concept of the grate cooler is quite simple

White cement cooler - thyssenkrupp Industrial Solutions

Especially for the white cement production process, thyssenkrupp Industrial Solutions developed the twin cooler, consisting of rotary cooler, roll crusher

Cement Euipment Overview | Cement Making Machines | Cement Plant

The cement cooler is also used for clinker production. Using blower blowing cold air, quench the cement clinker that laid on the grate plate, decrease the temperature of clinker from 1200℃ to 100℃ and below, the cooling exhaust gas enters into the kiln as secondary air. dryer In fact, every cement plant requires different cement equipment.

US2641849A - Cement cooler - Google Patents

Cement cooler Download PDF Info Prior art keywords cement casing air tubes cooling Prior art date 1950-09-22 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no

Evaluating the thermodynamic efficiency of the cement grate

ASPEN Plus and neural networks predictive model were used to model, simulate and predict the grate clinker cooler in this paper. First, the process flow model

Grate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

The grate cooler adopts a modular construction design, is flexibly adaptable to different scales of the cement kiln. There is no need of conveying equipment for material leakage under the grate

Clinker Grate Cooler for Cement Plant - Rotary Kiln

Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plant. Its main function is to cool and transport the

Kiln Cooler for Cement Rotary Kiln of Dry Process Method

AGICO supplies 2 types of kiln cooler equipment for cement production line, one is grate cooler, the other is rotary cooler, grate cooler is more efficient in cement plant, rotary cooler is suitable for many other industries.Grate Cooler is a type of quench cooler. Its works by quenching clinker which is laid in levels on the grate plates with

Impact of clinker coolers on downstream equipment

Clinker coolers in today's cement pyroprocessing lines are considered to be very reliable even under kiln upset conditions. But what is the interaction of

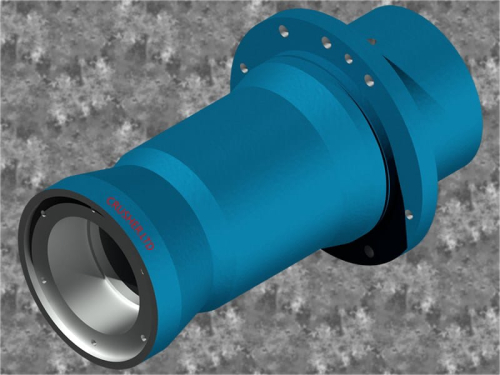

Rotary Cooler for Small Cement Plants | Rotary Drum

The latest type of rotary cooler can cool the fresh cement clinker to 150 ~ 250 ℃ and provide secondary air at 700 ~ 800 ℃ for the rotary kiln. Its overall thermal efficiency can reach 55% ~

Temperature control during clinker cooling process

Modern clinker coolers have an air flow perpendicular to the clinker flow, absor thermal energy. This hot air is used almost entirely as secondary air for

+86-21-63353309

+86-21-63353309

Leave a Comment