cone crusher liner change

Changing of crusher liners

Using crusher backing material to help change liners of 1000 maxtrac cone crusher.

Cone Crusher Mantles & Bowl Liners – Optimum Crush

Our relationship with multiple foundries minimizes risk and ensures the best price with liners made to our quality requirements. Optimum Crush® liners have led to as much as 50% increased life and/or 10% increased production. In nearly 100% of the tests conducted with Cone Crusher bowl liner, they have met or exceeded the current product.

Cone Crushers | McLanahan

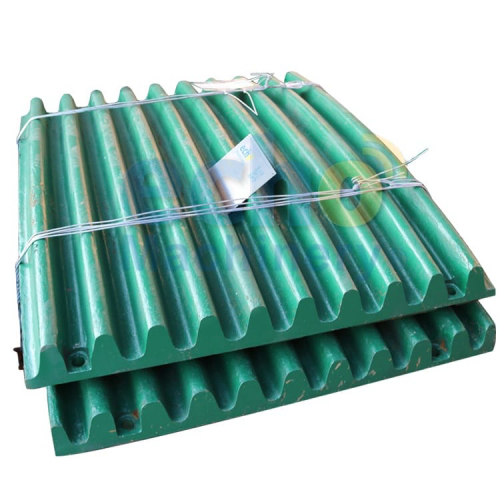

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Cone Crusher Liners: How To Select And When To Change - Weebly

Feed is the primary component of Cone Mill Liners Foundry. A well-graded feed should be utilized to crush the material. A feed that is graded properly should include: 90-100% passing the closed-side feed opening. Some people also look at the open side, and then choose the smaller one. 40%-60% at the middle 0-10% passing the closed-side setting.

When to change Cone Crusher liners - Cast Steel Products

A good indication the Cone Crusher liners need to be changed is when there is a 10% or more drop in production level or throughput. Liner thickness Depending on the application, If the

Change Cone Crusher Wear Parts - Precision Casting

There are two situations need to change cone crusher wear parts: Situation 1:Normal Abrasion. In order to avoid damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced before they are worn through. In normal conditions, approximately 50% of the liner weight is consumed when liners are worn out.

Cone Crusher Wear Parts - Columbia Steel Casting Co., Inc

OEM liners are based on average conditions, and few cone crushers work under replacement for zinc in both portable and permanent crusher applications.

Read now 9+ cone crusher liner most prestigious - Công lý & Pháp

1.Cone Crusher Liners: How to Select and When to Change; 2.World-Leading Crusher Liners – CMS Cepcor; 3.Cone Crusher Liners | Crushing Wear Parts – Cast Steel Products; 4.Cone Crusher Wear Parts – Columbia Steel Casting Co., Inc. 5.Replacing the liner of a HP cone crusher – Outotec; 6.Yong Won SP300 Super Cone Crusher liner

cone crusher liner change SG6089 CONCAVE SEGMENT MM Concave Double Upper

10 Steps To Install Cone Crusher. During installation, place the cone-shaped liner plate, place the thread ring on it, place the flange on the thread ring, clamp the snap ring on the outer neck ESCO CRUSHING - L.S.W. Wear Parts Ltd. Contact L.S.W. Wear Parts Ltd. for pricing and information.. Cone Crusher Wear Parts Cone Crusher Accessories.

How To Select Cone Crusher Liners and When To Change

The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing

Application guide ® MP Series™ cone crusher wear

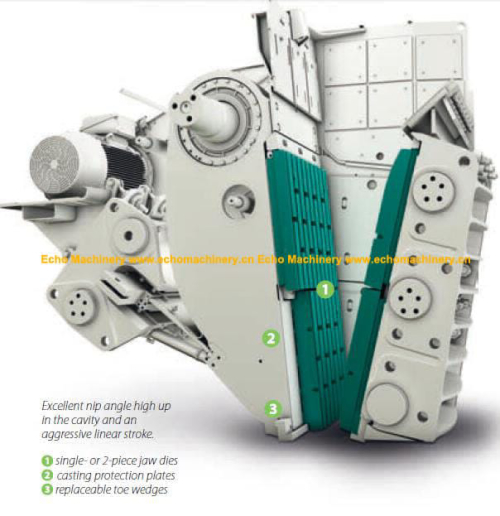

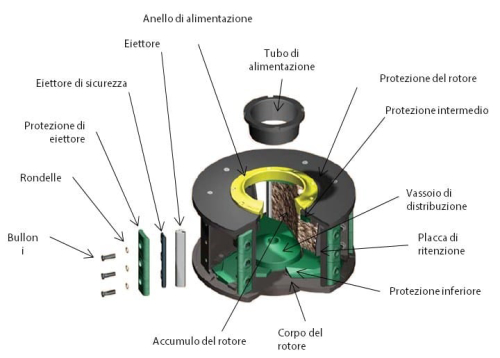

Installation of new bowl liner • Make sure bowl liner is centered in bowl • Replace wedges (shim as needed) • Tighten in criss-cross pattern: check seat area with feeler gauge, pour backing if required and place insulation around wedges Mantle removal 1. Remove feed plate (feed cone) 2.

+86-21-63353309

+86-21-63353309

Leave a Comment