cone crusher liner profiles

cone crusher liner profiles | giga crusher bottom shell bushing and

Cone crusher liner profile gauges have gained significant interest among quarrying producers in recent years. Using Your Blackhawk Cone Crusher For Mining Operations. 27/2/ · The cone crusher is best suited for medium or small sized operations that require a powerful, compact design. They work on a variety of mineral recovery plants.

cone crusher liner profiles | Z301 BOTTOM LINER BASE LINER "31" - RIGHT

An inadequate liner profile can lead to increased downtime through excess liner wear, low efficiency and, in catalogo-HP.pdf. liner as measured when they are at their Wear parts application guide - HP series cone crusher Check the wear profile of the liners: a. PDF MP series cone crushers Wear - s , Crusher parts

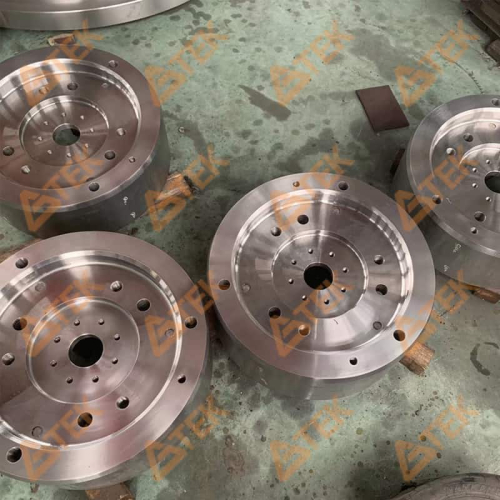

CME™ Crusher Liners - H-E Parts

CME™ Gyratory Crusher Liners. H-E Parts also specialize in the design and manufacturing of CME™ gyratory concaves in both manganese and liquid quenched Ni-Cr-Mo steels that have been proven to provide longer, more consistent life than most common air-quenched concaves, with far less risk of failure that can be encountered with white irons.

cone crusher liner profiles | qh cone crusher worm wheel list

1/1/1990 · When a liner has been in service for some time, the profile of the crushing chamber has normally changed substantially due to wear, as illustrated in Figure 6, which shows the new,.Cone crusher performance 113 worn and proposed liner profiles for the Mount Isa secondary crushers (Canning et al., 1988).

Cone crusher parts - Outotec

The right wear profile improves crusher performance and extends wear life, leading to less downtime and fewer liner replacements, which in turn increases safety and reduces the cost per ton. Our cone crusher wear parts are available for all Outotec crushing equipment, but we also offer crusher wears for non- Outotec crusher models.

Cone crusher basics in 4 minutes — SRP

This is the starting point for understanding how cone crushers work – and how to make sense of these it helps to understand the basics of cone crushing.

Cone Crushers: The Suppliers' Perspective | E & MJ

cone crushers feature a cam-and-lever crushing action, allowing them to work with many different liner profiles. The company states that in most

Crusher Wear Parts Reference Guide - Corporation

Cone Crusher Wear Parts. 4. Impactor Crusher Wear Parts. Topics within these sections include metallurgy options , liner profiles available , application

What is the wear profile of your crusher trying to tell you

After this webinar, you will: Be comfortable identifying and diagnosing liner related issues seen on most high-speed cone crushers, gyratory crushers, and jaw

CRUSHER WEAR PARTS

JAW & CONE LINERS 18% Manganese plates weight loss to the mass of tested material. The index Standard fit on all jaw & cone crushers. This is a liner suitable for all applications. 22% Manganese Optional fit for all jaw & cone crushers. Hardens quicker in abrasive applications. 14% Manganese This is an option & is ordered in on demand.

Cone Crushers | McLanahan

A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 4.5 inches. Reduction ratios of 8:1

+86-21-63353309

+86-21-63353309

Leave a Comment