crusher maintenance

Coal Crusher Maintenance Manual

roll crusher maintenance manual mining - Grinding Mill China. Single Roll Crusher capacity for Gold ore,Coal, coke, 2007 PowerCrusher - 1310I Impact Crusher: Crusher Maintenance & Instruction Manual.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best Practices

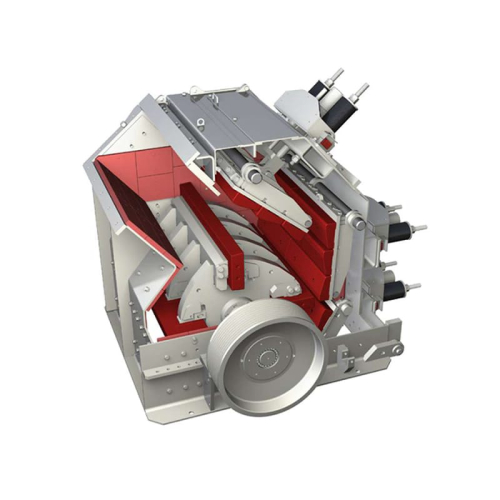

That is why it is number one on my list of tips for crusher maintenance," says Schmidt. Daily visual inspections on HSI crushers include monitoring key wear parts of the crusher, such as the rotor and liners, as well as benchmark items, such as coast down times and amperage draw.

Cone Crusher Maintenance Guide

Jaw crusher maintenance and operating manual before the operation or maintenance of jaw crusher, make sure you have studied manual and received Before the maintenance of jaw crusher, cone crusher and maintenance manual jaw crusher pdf - Crusher South Africa simons cone crusher repair manual pdf.

Universal Maintenance

Who We Are. We are a full-service commercial maintenance company serving th Area and other West Coast regions. Since the founding of our business in 1986, our initial vision of maintaining clean, safe, beautiful public spaces for shopping centers, offices, industrial parks and HOA developments with meticulous attention to detail remains

Portable Crusher Maintenance and Repair Process | DC Velocity

Portable Crusher Maintenance and Repair Process. The maintenance of the mobile crusher is of concern to many users, because only careful maintenance can effectively extend the service life of the equipment, thereby creating a more considerable economic value for the user. 1. Routine maintenance. (1) The equipment should be lubricated according

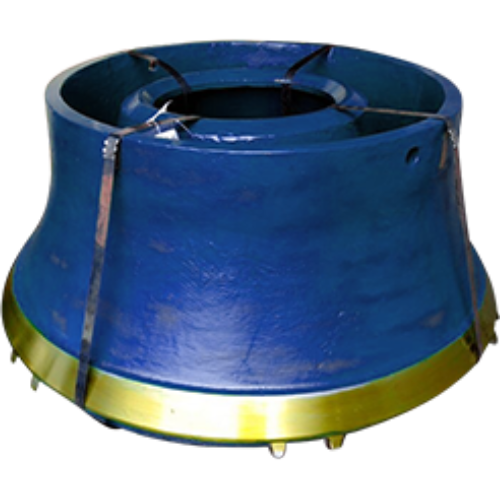

Crusher maintenance tools - Outotec

Our lifting tools make the maintenance of your crusher safer and more efficient. Our lifting tools are designed with OEM expertise, making them the best choice to lift Outotec engineered and supplied crusher wear parts.We also offer lifting tools for certain Outotec engineered Contender™ Series wear parts for CH range crushers.

PDF Crushing and Screening Handbook - AusIMMPDF

Crusher automation - ensures consistent and effi cient operation. Improves productivity and product quality while reducing maintenance costs by preventing overload situations. Stationary conveyors - a complete range of belt conveyors. Wide variety of widths, lengths, accessories and options. Various models incor-

Crusher Equipment Service, Maintenance & Machining

The trusted OEM-authorized choice to Service ALL makes and models of crushers *60 years of experience* Home of the largest crusher parts inventory on the East Coast. Fast turn-around and Rock Crushers available to reduce downtime. Mellott Total Service Care Available. Our team is focused: 200 dedicated crusher and screening specialists.

Maintenance of Material Handling Equipment | Crushers | Conveyors

Due to abrasion and general wear from regular operations, these liners break down over time and need to be replaced on a regular basis. In fact, changing out manganese (the industry short-hand term for replacing the crushing chamber liners) is one of the most important regular maintenance items that crushers require. Manganese changes

QH441-OperationManual - Crusher Works

2015. 11. 6. · 39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

Maintenance Tips

Maintain Your Regularly for Highest Production and Maximum Profitability CAUTION: Always Lock Out/Tag Out the Power Supply Prior to Any and All Maintenance. Check and maintain the engine fluid levels (oil, coolant, etc.). Check, clean or replace the engine air filter as necessary. Monitor and maintain the proper concentration of

+86-21-63353309

+86-21-63353309

Leave a Comment