crushing efficiency in size reduction

crushing efficiency of a crusher

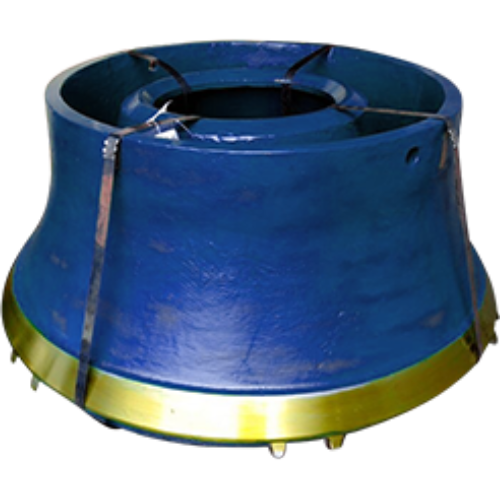

crushing efficiency of a crusher high efficiency cone crusher mantle germe edu.org ® HP Series™ cone crushers PFS Impact Crusher vipeakgroup.com Assessing the ene

PDF) size reduction(crushing) | Mhange Sungwa

3. Desired reduction ratio is not achievable in a single pass. 4. Over‐grinding is to be avoided. ffSize reduction theories fff Examples Example 1. Estimate the crusher motor power required to g reduce a magnetite ore from 80% minus 250 mm to 80% minus 90 mm at a

PDF Chapter 20: Size Reduction - Equipment for Size Reduction, Care and ...PDF

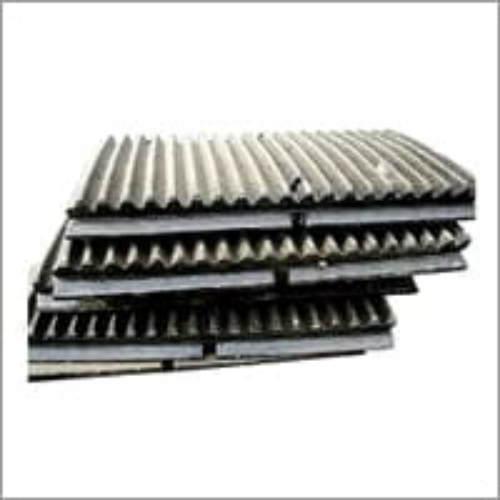

Size reduction is by compression, impact and shear and not by compression alone, as in the case of smooth roll crushers • Can accommodate larger particles than smooth roll crushers Crushing efficiency • Ratio of the surface energy created by crushing to the energy absorbed by the solid Grinders • Used to mill the grains into powder

Crushing Efficiency Factors - Mineral Processing & Metallurgy

The results are shown in Figure 3-17. It is seen that for a reduction ratio of 1.32, the relative efficiency of crushing a multi-layer of particles is 72%. Note that crushing ratios in a ball mill are not well defined, but are believed to range up to 1.5 or even 2.0.

Shredder & Crusher Systems for Size Reduction - RecyclingInside

10/7 · The Shredder Unit can be made with crusher and separator units according to customer demand. It is possible to reduce the grain size up to 1 mm if the shredder designed with the crusher. PCBs, which are electronic waste, is approximately 40×40 cm in size. They feed directly into the shredder and the resulting product size is in the range of 25

PDF Effects of Blasting on Crushing and Grinding Efficiency and Energy ...PDF

The Effects of Blasting on Crushing and Grinding Efficiency and Energy Consumption Lyall Workman1 and Jack Eloranta2 less energy will be required to crush the ore to the same product size. Second, a kg/ton (0.90 lb/ton), and that an associated reduction in P80 size to 30 cm in the blasted ore occurs. The work input, assuming no change

Calculate Crusher Efficiency Reduction Ratio

Reduction ratio calculation jaw crusher ematobeeu how to calculate jaw crusher reduction ratio Crushing of coal and calculation of size reduction efficiency Feb 25

Size Reduction and Energy Requirement - ScienceDirect

The mechanisms of size reduction during crushing and grinding are different. The chief difference is that in crushing operations the size reduction is more by compression and impact and less by attrition while in grinding; the forces of attrition are much greater. This efficiency factor is only used when R is outside the range R RO ± 2. 7

What Is Crushing Efficiency

Crushing Of Coal And Calculation Of Size Reduction Efficiency Feb 25, Crushing efficiency has been defined in the literature from the power consumption point of view. But while operating a process plant, it is important that the crushing efficiency is defined in terms of the requirement of subsequent process.

size reduction - SlideShare

In general, a crystalline material will break along well-defined planes and the power required for crushing will increase as the particle size is reduced. Stickiness: A sticky material will tend to clog the grinding equipment and it should therefore be ground in a plant that can be cleaned easily.

Process and equipment selection for improving crushing efficiency

The crushing section refers to the process to reduce the size of particles by impacting, shearing and grinding. It is one of the most important basic processes of wood pellet plant. The energy consumption of crushing section accounts for 70% of total energy consumption of the processing factory. Therefore, improving the crushing efficiency of

+86-21-63353309

+86-21-63353309

Leave a Comment