crushing in mineral processing pdf

Handbook of Crushing - TerraSource Global

The ability to crush material is governed by the laws of physics involving mass, velocity, kinetic energy and gravity. However, it is impractical to reduce the process of selecting and sizing a crusher to a series of formulas. The selection process is largely based on experience and testing — experience with actual

PDF AP-42 Section 11.19.2 Crushed Stone Processing and Pulverized Mineral ...PDF

for these products, pulverized mineral processing plants have production rates that are less than 5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2. In dry processing systems, the mineral aggregate material from conventional crushing

Crushing in Mineral Processing

26/12/ · In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different

PDF OP05 - Mineral Processing (Crushing & Screening) - Agg-NetPDF

The purpose of this document is to prepare procedures covering the control of crushing and screening operations. What does the responsible manager need to do? The responsible manager must ensure that: All parts of the processing plant are suitably inspected and maintained as per Regulation 12(1)(a)(iii) Quarries Regulations 1999

FULLTEXT01.pdf - DiVA portal

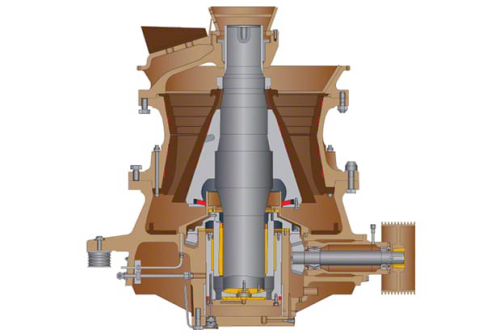

the aggregates and mineral processing industries, run-of-mine ore is broken in crushing circuits by cone crushers.

PDF Minerals Handbook - selfies.cricket.com.auPDF

C series jaw crusher Manual SlideShare. mining minerals crushing and screening handbook. Crushing and EN PDF â€" Basics in mineral processing com. www com. Screening media Handbook danskgm dk. Safety standards as applied by Minerals on mobile. Metso’s Crushing and screening

Comminution - University of Technology, Iraq

In order to separate the minerals from gangue (the waste minerals), it is necessary to crush and grind the rock to unlock, or liberate, valuable minerals so that they are partially or fully exposed. This process of size reduction is called comminution. The crushing and grinding process will produce a range of particles with varying

11.19.2 Crushed Stone Processing and Pulverized Mineral

Major mineral types processed by the pulverized minerals industry, a subset of the crushed stone processing industry, include calcium carbonate, talc,

PDF Comminution - University of Technology, IraqPDF

Wet grinding is generally used in mineral processing operations because of the overall economies of operation. , The advantages of wet grinding are: , It consumes lower power per tonne of product. , It has higher capacity per unit mill volume. , It makes possible the use of wet screening or classification for close product control. ,

PDF) Mineral Processing: Crusher and Crushing - ResearchGate

08/11/ · Abstract. Mineral Processing: Crusher and Crushing; Types of Crusher; Types of Crushing; Local Quality and High quality ; International and Country/Hand made. Content

mineral processing handbook - AusIMM

Mineral Processing Handbook 11/11 - 1st printing Printed in U.S.A. TABLE OF CONTENTS SECTION I PAGE 6–163 All along the processing line, Feeders, Grizzlies, Crushers, Scalpers, Classifiers, Washing Plants, Sizing Screens, Conveyors, Equipment is

+86-21-63353309

+86-21-63353309

Leave a Comment