crushing plant process

Crushing | McLanahan

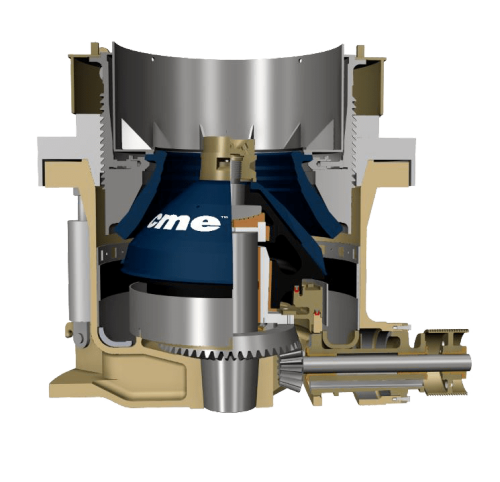

As feed material advances downward through the chamber, it is crushed between the moving piece of steel and the stationary plate. Only material that has reached the desired size passes on to the next stage in the process; whereas the larger material remains subjected to repeated pressure in the chamber until it, too, reaches the desired size.

Crushing Plant Philippines - Stationary And Mobile Type Crusher Plant

The mobile crushing and screening plant can process the raw materials in site, reducing its transportation process and greatly saving the transportation cost. Customize the specific type of mobile crushing plant for our customers. Depending on the customer’s requirement, we can greatly combine with different crusher machine for sale.

Kernel Crushing Plant Process Presentation | PDF - Scribd

1. Kernel Crushing Plant Process Presentation - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Kernel Crushing Plant KERNEL CRUSHING PLANT PROCESS PALM KERNEL KERNEL QUALITY : M+I = 6.0% D+S = 7.0% OIL C = 52.0% PALM KERNEL HOPPER PALM KERNEL SILO

Crushing & Screening Plant - Mineral Processing & Metallurgy

Common Crushing Plant Design & Layout. New Crushing Technologies. Methods used in Crushing & Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers. Crushing is done underground at a few large mines.

Aggregate Crushing Plant | How to Run a Crushing Plant - JXSC Mine

2.1 One time crushing process Jaw crusher VS impact crusher 2.2 Multiple times crushing process Check the capacity by considering the nominal feed opening, closed side setting S.S.S and crusher type, then choose the reasonable equipment. If need four times crushing process, the gyratory crusher usually is the fourth crusher.

Crushing Plants - Westpro Machinery

Equipment Commonly Utilized in Crushing Plants · Agglomerators · Apron Feeders · Cone Crushers · Drum Scrubbers · Grinding Mills · Hopper Feeders · Jaw Crushers.

Aggregate Crushing Plant and Processing - JXSC Rock Crusher

Aggregate Crushing Plant & Processing Equipment Abstract Sand and gravel aggregate production mainly include dry and semi-dry processes. Dry production means that the process of the entire production line is basically free of water. This dry type aggregate production process is mainly adopted in northern China.

What Does The Crushing Plant Consist Of? - Fabo

What Does A Crushing Plant Consist Of? · Bunker (Feeder) · Primary Crusher (Jaw Crusher) · Conveyor Belt · Vibrating Screen

Stone Crushing Process And Products - Crusher Mills

Finished Products Of Stone Crushing Plant - process crusher. The is the professional mining equipments manufacturer in the world, located in China,India, along with other Asian marketplaces to develop and develop, now we

Quarry Crusher Plant - Crushing & Screening Plant - AIMIX Group

Process flow of quarry crusher plant. The raw material is transmitted evenly by vibrating feeder to jaw crusher for tough crushing. After rough crushing, the stone is transmitter by belt conveyor to impact crusher for fine crushing; after fine crushing, the stone is transmitted by belt conveyor to vibrating screen for screening and classification.

Environmental GUIDELINE ON STONE CRUSHING plant

The processes involved in stone crushing include pre-processing, crushing, washing, screening and recycling of wastewater. • Pre-processing consists of removal

+86-21-63353309

+86-21-63353309

Leave a Comment