maintenance of jaw crusher

Crusher Service | Maintenance & Servicing - CMS Cepcor

Regardless of your chosen supplier, it is vital that any crusher repair (even with severe production demands to get back up and running) should consider

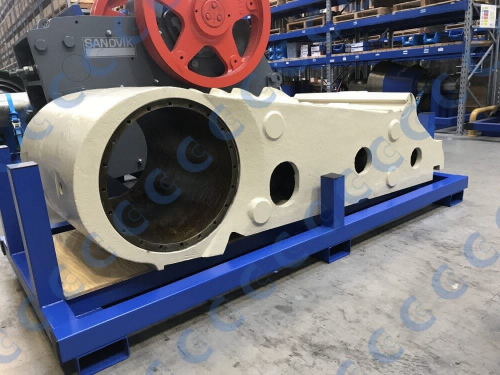

Construction, Working and Maintenance of Crushers for

As shown in above figure, a jaw crusher consists of a set of vertical jaws. The volume or cavity between the two jaws is called the crushing chamber. The gap

The Daily Maintenance of Jaw Crusher

The rough crushing of the jaw crusher cannot be replaced by any machine. However, in the production process, the jaw crusher also has a failure rate, and the service life is greatly reduced. Therefore, it is necessary to carry out regular maintenance and maintenance of the jaw crusher. Check before start

Maintenance of Jaw Stone Crusher

Jaw stone crusher are known as jaw crusher and usually operate under harsh working conditions. When using, it is necessary to strictly abide by the operation rules and maintenance system, find and repair the worn parts in time, and eliminate various faults. Maintenance of Jaw Stone Crusher. 2022-07-11 17:32:30. SHARE TO: Jaw stone crusher

Maintenance Procedure Of Jaw Crusher

maintenance schedule for jaw crusher | Mobile Crusher Philippines. If we make periodic maintenance schedule for jaw crusher, lubrication system, change lubrication oil etc. Its period is 1~3 months. 2. Medium repair of jaw crusher.

Maintenance of Jaw Crusher - Knowledge - Shanghai

Jaw crusher is widely used in mine, metallurgy, high way, railway and water conservancy industries, the compression strength of jaw crusher is not exceed 320 Mpa when jaw crusher designed by the specialist.. Jaw crusher wear phenomena in daily operations is inevitable, we have to do regular jaw crusher maintenance to extend the useful life to the maximum, so we

Tips for Crusher Maintenance - Thomasnet

Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies every day, and make sure bolts are fastened securely. Maintain crusher backing to ensure proper vibration and impact protection. Keep breathers clean. Make sure the toggle area is clean, especially prior to any adjustments.

Jaw crusher maintenance | Henan Deya Machinery Co., Ltd

First of all, the ore feed must be stopped, and after the ore in the crushing chamber is all discharged, then stop the crusher and belt conveyor. It should be noted that if the crusher stops suddenly for any reason, the accumulated ore in crushing chamber must be cleared before the crusher is ready to start again. Maintenance and repair

5 Tips for Jaw Crusher Operation

Jaw crusher is widely used in mining industry because of its simple structure, reliable work, convenient maintenance and low production cost.

Daily Maintenance Of Jaw Crusher - News - Hysan Road

Apr 10, · Daily Maintenance Of Jaw Crusher. Apr 10, . 1. Check the heating of the bearing. For rolling bearings, the temperature cannot exceed 70°C, and for sliding bearings, the temperature cannot exceed 60°C. If the temperature exceeds the specified temperature, stop immediately for inspection and troubleshooting. 2. Check whether the lubrication

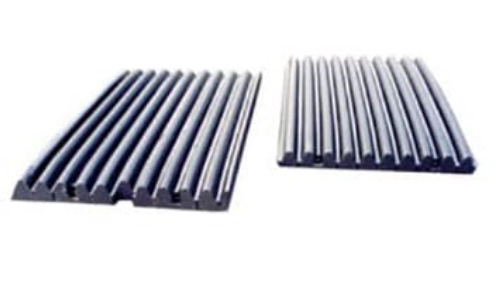

Jaw and Impact Crusher Maintenance - RR Equipment

Dec 20, · I would say that in general, yeah, there’s definitely some maintenance involved with crushing. Typically we’re looking at the wear parts or the actual parts of the crusher that are impacted by the material. So if it’s an impact crusher it would be the blow bars. If it’s a jaw crusher it’s the jaw dies or jaw plates.

+86-21-63353309

+86-21-63353309

Leave a Comment