double roller crusher design

Double Roll Crusher Design - Gordon van Veelen

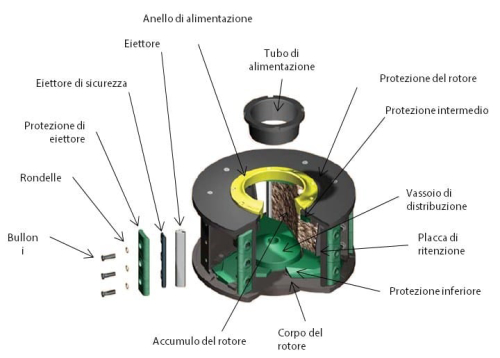

Apr 24, DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedge.The wedge

New Double Roller Crusher by Bedeschi

4/22 · Since almost 50 years, Bedeschi is also specialized in the design and the manufacturing of double roller crushers. Part of the continuous research and development effort of Bedeschi is the new latest technology of the double roller crusher heavy duty (type RL).

What's a Double-Roller Crusher?

What are the characteristics of double-stick crushing and sand making? Roller design, can process both wet and dry materials. The wear cycle of

new design double roller crusher for goat feed

Stone Crusher ,2PG SERIES DOUBLE ROLLER CRUSHER Feed size: up to 2500 up to 12000 mtph (13228 stph) , 2 ADVANCED DESIGN, HIGH PERFORMANCE crusher capacity vs feed size - Newest Crusher, Grinding Mill ,.

CPC Double Roll Crusher - SIEBTECHNIK TEMA

CPC Double Roll Crusher - Coarse size reduction of hard and medium-hard Design of crushing teeth according to the material requirements (number, size,

Double-roller Crusher - Shuliy Machinery

The double-roller crusher is mainly used for crushing ore. This machine has the advantages of small size, good crushing effect, low noise, simple structure, convenient maintenance, uniform size of crushed materials, sensitive overload protection, safety and reliability. It is suitable for coal, metallurgy, mining, chemical, building materials

Double Roller Crusher Design By Tata [vnd5r12d6wlx

TECHNICAL SPECIFICATIONS TECHNICAL SPECIFICATIONS = Length and width of roller screens can be adjusted to suit customers' requirement = Non clogging, smooth, non-vibrating and low noise while running = Higher screen efficiency = Less space required = Higher capacity up to 1500 TPH running at low power compared to conventional screens

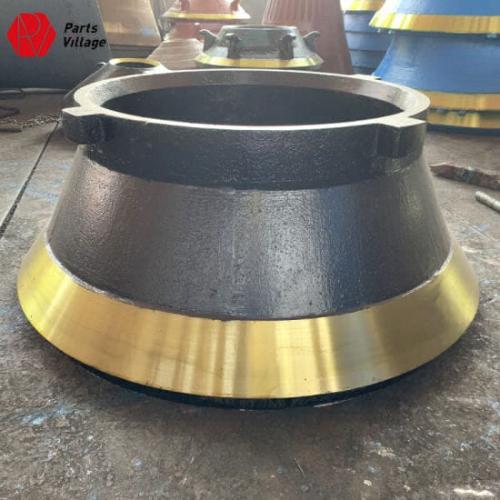

Roll Crusher| Double Roller Crusher |DOVE

6/25 · Double Roller Crusher. DOVE Roll Crushers are designed with compact structure, small space installation, Light weight, Convenient operation, and low maintenance. DOVE Tooth Roll Crushers are

double crusher roller teeth design calculations - GodSend

11/13 · Double Roll amp Teethed Roll Crusher. Feb 24, Feb 24, The single-roll crusher has a tip speed of 400-450 ft/min while the 6- x 7-ft teethed roll crusher has a normal, no-load, surfaces speed of just under 3500 ft/min. It can be readily appreciated that this high velocity induces an extremely violent crushing action, in conjunction

Double Roll Crusher Design Principles

Double Roller Crusher Design Vakhusicoa Roll Crushing 911 Metallurgist. Feb 23 The crushing action of roll crushers on rock is completely by compression. Moreover the actions of the single and doubleroll forms of this type . for crushing hard rock or

Roll Crushers - Top 2022 Models - 911 Metallurgist

The standard spring roll crusher have two horizontally mounted cylinders. for crushing hard rock or ore. roll crusher design chart and crushing capacity.

+86-21-63353309

+86-21-63353309

Leave a Comment