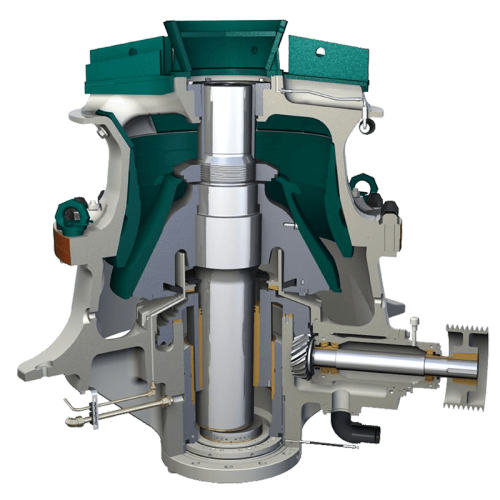

sag mill

Pre-Processing to Increase the Capacity of SAG Mill Circuits

Simulations indicated that a capacity increase of 12% would be achieved in the existing grinding circuit by further crushing 35% of SAG mill

SAG mill increases productivity, reduces unscheduled

Industrial milling of mined ore – from large rocks and boulders to fine particles – is a demanding process. Massive semiautogenous mills – commonly known as SAG

SAG Mill - Official Feed The Beast Wiki

The SAG Mill is a machine added by Ender IO. It uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into Dusts. The SAG Mill has four output slots;

What's the difference of Ball mill, SAG mill, AG mill?

A Sag mill is most often used in the mining fields, particularly in the mining of precious metals such as gold, copper, silver, and nickel. The sag mill serves in the line of industrial mining equipment designed to process, crush, separate, or locate precious metals from mined coal.

SAG Mill Liner Types - MGS Casting

The style of a SAG mill liner is driven by the material of building and construction and also the application, as well as limited by casting, molding, and taking care of constraints. For huge mills with wide inlet trunnions, in excess of 1.5 m, liner handling types of equipment are currently in common usage, and

Enhanced SAG Mill - Official Feed The Beast Wiki

The Enhanced SAG Mill is a machine added by Ender IO. It uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into Dusts. The SAG Mill has four output slots; recipes can have 1-4 different outputs, with different chances of obtaining those outputs.

Advanced Sag Mill for Efficiency in Mining

Find the right Mining Machinery from Alibaba.com. Explore our mining equipment to find the ideal wholesale sag mill model and mills for any mining

SAGMILLING.COM .:. Home

Grinding circuit design tools, including for SAG mill-ball mill circuits, and geometallurgy energy models are available to subscribers.

Used SAG Mills | Buy & Sell | XXX - Machinery and Equipment

4) Sag mill, 22' diameter x 7' long, manufactured by Hardinge, with (2) tacke gearboxes, type NI Add to cart Mill, Sag, 18' X 6', Hardinge, 1000 HP, #D735558

What’s the Difference Between Ball Mill, Rod Mill and SAG Mill?

Mar 20, · SAG mill: Types of material : Almost all materials: 1.Rough grinding 2.Brittle materials, such as tungsten, tin ore before gravity concentration: Dry SAG mill: asbestos mine, silicon carbide, etc. Wet SAG mill: minerals with mud (can omit ore washing) Feeding size: ≤25mm: ≤50mm: 300-400mm: Capacity : 0.62—180t/h: 0.65—615t/h: 1.5-338t/h: Discharging size

SAG mills - ERSEL Ağır Makine San. ve Tic. A

SAG mills are the machines with the highest reduction rate which performs crushing, grinding and washing together. It offers a much higher reduction ratio

+86-21-63353309

+86-21-63353309

Leave a Comment