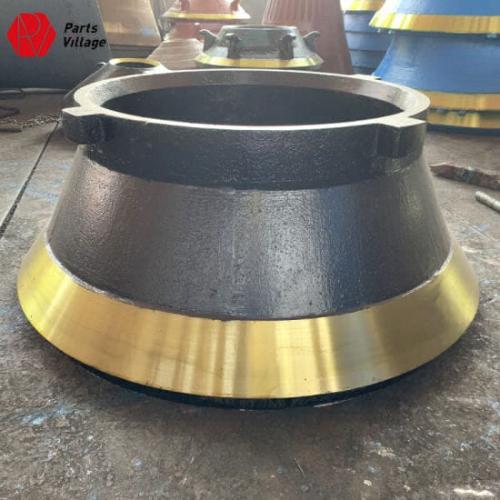

cone crusher mantle

Constant Wear Criterion for Optimization of the Crushing

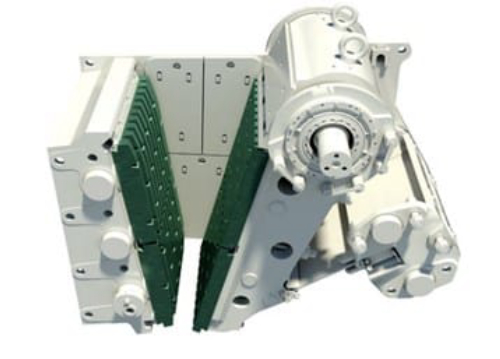

prototype of a ZS200MF cone crusher with an optimized mantle and concave Cone crushers are high-efficiency particle crushing instruments

Cone crusher mantle

High manganese steel moving cone for cone crusher. ZTIC offers a wide range of concave (bowl liner) and mantle suit cone crushers, including:

Mantle Liner | Cone Crusher Parts | HANDY - Steel Castings

HANDY is proud to manufacture mantle liners for various cone crushers to customers' specifications.

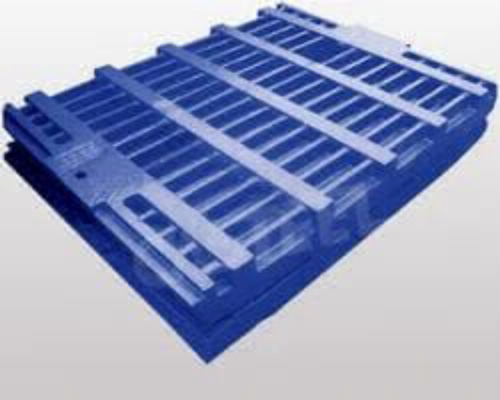

Bowl Liner & Mantle | Wear Resistant Crusher Parts - GTEK

Cone Crusher Mantle & Bowl Liner are used for compressing rocks and ores into small size. GTEK provides OEM interchangeable mantles & bowl liners with long

The importance of the right mantle and concave — SRP

To get the best out of your cone crushers, you need to balance three important factors – the feed, the eccentric throw, and the closed side setting (CSS).

Cone Crusher Parts_A professional concave、mantle liners

Common Aliases:Concave, mantle, bowl liners, cone crusher parts, cone liners · Main Material:High manganese steel (Mn13, Mn13Cr2, Mn18, Mn18Cr2) · Casting

Mantle parts for crushers

Mantle parts for crushers Cone crusher is widely used in metallurgy, construction, mining and other industries, can be used for secondary or third crushing. Obviously, the most frequent wearing parts in cone crusher are the mantle and bowl liner. Our cone crusher liners range from: Mn13Cr2, Mn18Cr2 and Mn22Cr2 according to your application.

Cone Crusher - Westpro Equipment

The vertical cone crusher drive shaft rotates the mantle eccentrically below the concave, or bowl liner, squeezing the product and crushing it between the

China Mantle For Cone Crusher Factory and Suppliers

Mantle For Cone Crusher Manufacturers, Factory, Suppliers From China,

cone crusher Removing mantle nut

1000 cone crusher . This video shows the process of cutting a mantle to release the pressure off the mantle nut so you can undo it.If you value

Cone Crusher - an overview | ScienceDirect Topics

Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs. Wear monitoring is possible using a Faro Arm (Figure 6.10), which is a

+86-21-63353309

+86-21-63353309

Leave a Comment