moving jaw plate

Swing Jaw Plate and Moving Jaw Plate Apply to Jaw Crusher

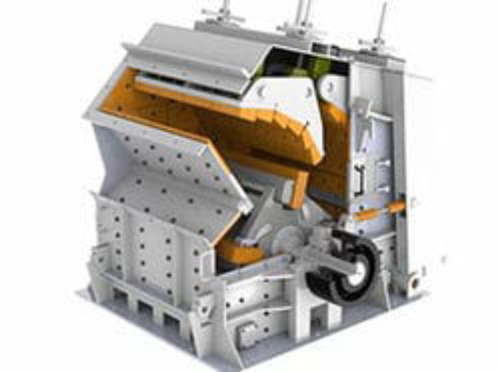

Name: Jaw crusher plates. Jaw plate has two types: fixed one and movable one. These two parts are the part that has the most contact with the stones and they are the easliest to be worn. Other parts like Toggle plate, Toggle seat, Adjustment seat, Cheek plate, Pressing bar, Spring and Tension rod also need to be replaced frequently. F&Q. 1.

The reason why the moving jaw does not move in the mobile

The most common reason why the movable jaw plate stops moving is that the equipment is damaged, unbroken objects or other irrelevant broken materials, causing the thrust plate to break or the

Jaw crusher pare Wear Parts Jaw Plate Moving and Fixed Plate

Jaw Plates | Jaw Crusher Parts | HANDY. Jaw plate, also called toothed plate is the key wear-resistant part of jaw crusher. A set of jaw plates generally consists of a movable plate and a fixed plate. They work together to crush materials. The crusher parts come in various profiles and sizes for different jaw crushers.

Fixed Moving Jaw Plate Crusher Liner Plate for Mining

China Mantle, Bowl Liner, Conncave, Fixed and Swing Jaw Plate Jaw liner (fixed and swing jaw liner) are the most important wear parts of jaw crusher. We use high manganese steel with

Customized crusherpare parts moving and fixed jaw plate tooth plate

In order to protect the jaw plate, wear-resistant lining plates are generally installed on the surfaces of moving and fixed jaw plate. This type of liner is also called a crush plate. The surface of the crush plate is usually made into tooth shape, the angle of the tooth peak of the crush plate is 90 °/ 120 °, and its size is determined by

Aggretek moving jaw plate for crusher – Aggretek double spiral

Tell Us What You're Looking For. Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Crusher Jaw Plates For Popular Brands By Hunan JY Casting

Premium Crusher Jaw Plates. The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed jaw plate and a 1 piece movable jaw plate. In order to rotate and exchange more easily, movable jaw plates also have 2 segments design and 3 segments design.

Crusher Moving Jaw Plate

these instructions are valid for both moving and stationary jaw. remove the jaw plate before removing a wear plate. if a jaw shim plate is used, there is no wear plate. exchanging jaw crusher wear plates steps: position the hook of a mobile crane vertically above the wear plate (3100-0). be aware of the weight of the wear plate. make sure the

Fixed Moving Jaw Plate Crusher r Plate for Mining Manganese

Fixed Moving Jaw Plate Crusher r Plate for Mining Manganese Cast Wear Parts. Jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc. The pressure resistance strength is under 200Mpa

News - Exchanging jaw plate

Always use the referred lifting cavity on the jaw plate and the lifting tool provided with the jaw crusher. Removing jaw plates. Remove the props between the jaws. Be aware of the weight of the jaw plate. Make sure the moving jaw is reclined so that the jaw plate will not fall forwards while releasing the jaw plate or uncovering the lifting cavity.

Facial Trauma/Jaw Fracture Surgery near Hillsboro, OR

Find top doctors who perform Facial Trauma Jaw Fracture Surgery near you in Hillsboro, OR. Book an appointment today! LIST YOUR PRACTICE ; Dentist ; Pharmacy ; Search . Find a doctor near you. Search doctors, conditions, or procedures . The location you tried did not return a result. Please enter a valid 5-digit Zip Code.

+86-21-63353309

+86-21-63353309

Leave a Comment