gyratory crusher lube system

Primary Gyratory Crushers Failure Lubriion System

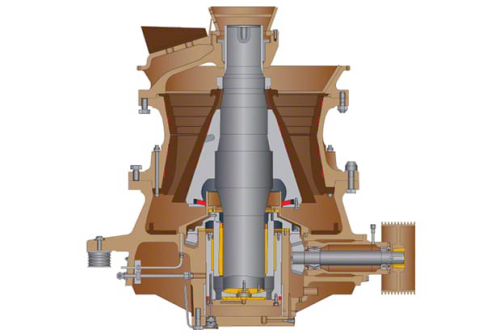

Gyratory Crusher Lube System YouTube. 8-2- How a Gyratory Crusher Lube System Works: Certain components in the crusher (pinion shaft and bearings, pinion and eccentric gears, eccentric bushing, and step bearing) require continuous oil lubrication. Auteur: 911 Metallurgy Corp. NEW lubrication system

CVB2050 RUBBER LINER | gyratory crusher lube system

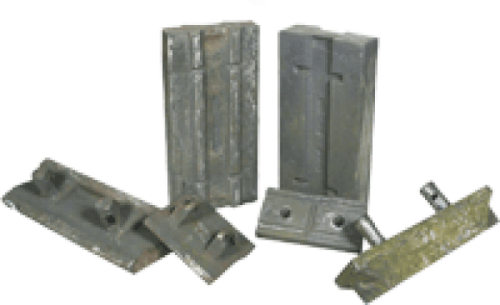

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, and Ball mill liners and Forged steel balls. We supply wear parts to the USA, Canada, Europe, Australia and Africa. Gb Th Cat Gen Complet Low Res - Calaméo

Gyratory Crusher - an overview | ScienceDirect Topics

5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described

Crusher Lubriion Principle

The mining crusher equipment divides into jaw crusher, gyratory crusher, impact crusher, Working Principle Of Cone Crusher''s Lubrication System.

Gyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Gyratory Crushers - Mineral Processing & Metallurgy

PINIONSHAFT ASSEMBLY for a 42-65 Gyratory crusher. Spiral bevel pinion mounted on turned steel shaft in cast steel housing. Anti-friction bearings. Assembly is independently lubricated. Seal plates and oil seals on both ends of housing. Spiral bevel gears allow a broad range of speeds. Eccentricity Adjustable to Capacity Demands

gyratory crusher lube system working

Jul 18, · The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to. This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore

Gyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name “Top Service”.

Gyratory Crusher Lubrication System Pdf

Lubrication System Minerals Inc. 1. A lubrication system for a gyratory crusher, comprising a thrust bearing, a lubrication piston and adjusting piston arranged to be movable in a cylinder wherein the piston comprises a first space configured to receive fluid and to continuously conduct the fluid to the thrust bearing wherein the cylinder and the piston define therebetween a second space

fr/analyse gyratory crusher gear system.md at main - GitHub

CMS Cepcor system to suit 3' Standard and Shorthead.Manufactured in the United Kingdom.CMS Cepcor lubrication system.Compatible with all 3' cone crushers

SUPERIOR® gyratory crushers - Automation - PDF Catalogs

superior gyratory crusher features 1 crushing chambers are matched to each individual application, optimizing crushing performance 7 patented headnut with burning ring allows for simple removal of the mantle 2 manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 high-strength shell design,

+86-21-63353309

+86-21-63353309

Leave a Comment