crushers liners

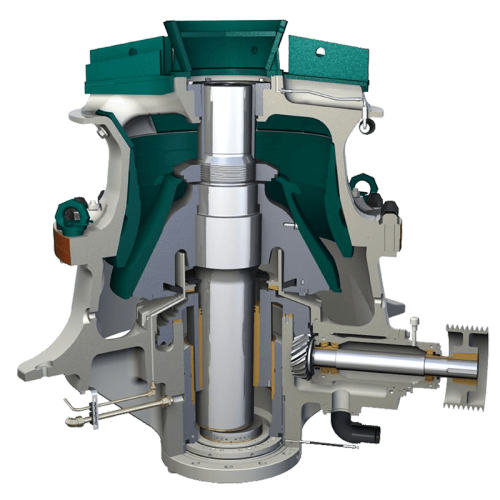

kpi 300 kodiack cone liners | alll spare sleeves of shaft assembley of

Patented liner retention assembly. Bronze field replaceable V-seat liners. Crusher Spares - wear resistant castings for cone crushers. Crusher Spares for wear resistant castings for mining, quarry, agricultural, earthmoving, and general heavy engineering machinery spare parts. find kodiak 400 cone crusher | Used Kpi Jci Kodiak 200 Cone Crusher

Cone Crusher Liners | Manufacturing and service of Gyratory

Increase your crushing productivity with our expert process know-how and high-quality equipment. We are the OEM manufacturer of Raptor® Cone Crushers.

Crusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

What We Offer. Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands.

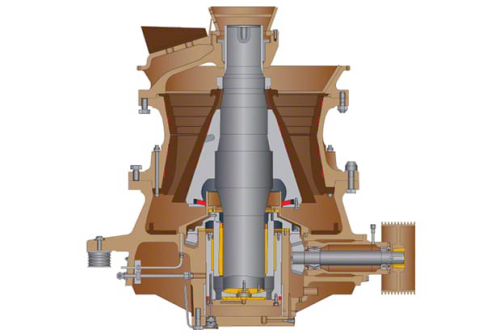

PS - MS - MILL - Crushers - Gyratory Crusher Liners

Gyratory Crusher Liners. Customised liner configurations, both in profiles and concave setup are reviewed to suit all operating conditions. Mantle design and size is optimised to match concave wear and maximise main-shaft travel. Manganese grades to cover all applications, additional premium grade alloys and white-irons to suit concave crusher

Cone Crusher Liners For Popular Brands With Various Material

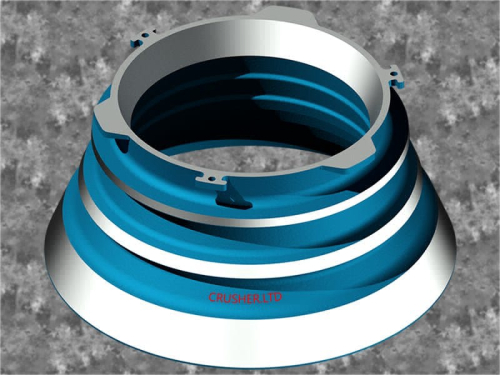

Cone crusher liners mainly wear parts in the cone crusher, which are included cone crusher mantle and cone crusher concave. Cone crusher mantle, which covers the cone head of the crusher to protect it from wear. It is the inner sacrificial wear liner that sits on the cone head.

AR Steel Crusher Liners - Crusher Wear Liner Supplies - Ford Steel

Ford Steel offers Wearalloy 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy plate up to 4-inches thick for AR steel crusher liners in impact, jaw, cone and other types of crushers. Wearalloy Superclad available for use as cheek plates too. Our company provides crusher wear liner supplies to a wide range of industries including: Sand & Gravel

Cone Crusher Mantles & Bowl Liners - Optimum Crush

Our relationship with multiple foundries minimizes risk and ensures the best price with liners made to our quality requirements. Optimum Crush® liners have led to as much as 50% increased life and/or 10% increased production. In nearly 100% of the tests conducted with Cone Crusher bowl liner, they have met or exceeded the current product.

Gyratory Crusher Liners - Bradken

Bradken's crusher liner product range is designed to provide the safest solutions for product installation and materials handling, optimal performance in

THOR liners for crushers by Element Global

an increased operational life. When compared with cheap products of Russian and Chinese production, the use of modified steel for the manufacture of THOR liners has made it possible to increase the life capacity of the bowl liner from 660 to

Liner wear in jaw crushers

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these

R Crusher Wear Parts Reference Guide

Standard fit on all Jaw & Cone crushers. A good all round liner for all applications. 22% MANGANESE Optional fit for all Jaw & Cone crushers. Work hardens quicker in abrasive applications. 14% MANGANESE This is an option that & available if required although not generally stocked. For use in soft low abrasion applications.

+86-21-63353309

+86-21-63353309

Leave a Comment