primary crusher design aggregates pdf

Primary Crusher Pdf

Primary Crusher Pdf. 202017Primary impact crusher uses high wearresistant materials and the best crushing chamber which makes extraordinary performance and is very suitable to crush various kinds of soft medium hard ore rough pieces of material widely used in metallurgy mining cement chemicals refractory and ceramics highway construction water conservancy

PDF MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE - Mining and ...PDF

1. A typical example of primary crushing is reducing topsize from 900 to 300 mm. 2. A typical example of secondary crushing is reducing topsize from 300 to 100 mm. 3. a typical example of fine crushing is producing concrete aggregates in fractions below 30 mm. 4. Manufactured sand is typically smaller than 5 (often 2) mm. 5.

Aggregate Crusher In Pdf

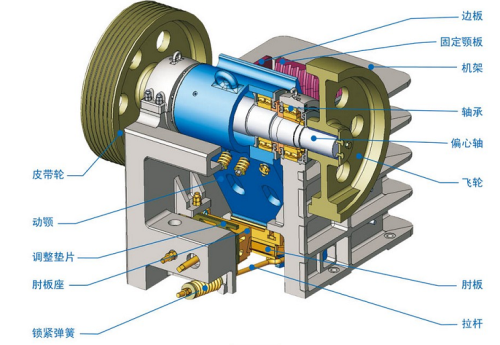

Crusher Machine Aggregate Making Plant Manufacturer A jaw crusher is generally used as a primary crusher in a crushing circuit Product is fed into the top of the jaw crusher by a vibrating grizzly feeder The eccentric rotating drive shaft causes the movable jaw to

crusher track parts | primary crusher design aggregates pdf

concrete crusher bucket primary gyratory crusher hp500 prssr rel valve rdba-lcn 230 bar huba control pressure switch 604 hydraulic pressure relief valve diagram. concrete crusher bucket primary crusher design aggregates pdf jaw crusher parts australia 1756-pa72 manual crusher for sale. Skid Steer Tracks, Rubber Tracks

Automated process control system of Jaw crusher production

Aggregate crushers suffer from many problems in reality that affect its production jaw crusher kinematics Journal of Engineering, Design and Technology.

crusher cone liner | primary crusher design aggregates pdf

The HP cone crusher is a very important piece of equipment in a crushing plant. It can operate as a secondary, tertiary or quaternary cone crusher operation with best quality cone crusher wear parts primary crushers hp400 tube G10SEC DRCTNLVALVE&CNNCTN CVUA-6-PDN-2-M-U-D-1 thermomax hp400 evacuated tube collectors

Aggregates for Concrete, Chapter 5 - Civil Engineering

Crushed stone is produced by crushing quarry rock, boul- ders, cobbles, or large-size gravel. design. It is not generally used as a measure of aggregate.

PDF Crushing Plant Design and Layout ConsiderationsPDF

The principal design parameters that drive crushing plant selection and configuration include: • Production requirements • Capital cost • Ore characteristics • Safety and environment • Project location • Life of mine/expansion plans • Operational considerations • Maintenance requirements • Climatic conditions

Enhanced Plant Design for Aggregate Processing | Agg-Net

The grid bar spacing prior to the primary crusher is, therefore, a very effective way to enhance capacity within a plant, without compromising overall performance in any way. In addition to the scalping screen, a separate, small, two- or three-deck screen is a very useful inclusion for processing the ‘unders’ from the scalper.

PDF Construction Aggregates - Building WastePDF

COMEC primary impact crushers are ideal for the crushing of non-abrasive rock and achieve optimal grain forms together with high crushing performance. The easy access to the chamber makes the COMEC primary impact crusher particularly easy to maintain. Its long service life due to the interchangeable wearing plates makes for a

Optimization of Aggregate Production Circuit through ... - MDPI

Abstract: The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral

+86-21-63353309

+86-21-63353309

Leave a Comment