grate cooler design

EP0525380A1 - Grate cooler - Google Patents

The invention relates to a grate cooler, in which the drive device is surrounded by a drive housing, the inner space of which is sealed in an airtight manner in relation to the atmosphere, but on the other hand has a pressure-equalisation connection to the inner space of the cooler housing. Such a grate cooler is characterised by considerably reduced expenditure for sealing the cooler

Grate Cooler - INFINITY FOR CEMENT EQUIPMENT

This design delivers high degree of utilization and minimize overhaul maintenance costs due to eliminating

Optimization Design of the Grate Cooler Based on the Power Flow Method

As an important process during the cement production, grate cooler plays significance roles on clinker cooling and waste heat recovery. In this paper, we measured experimentally the heat balance of the grate cooler, which provided initial operating parameters for optimization.

Clinker Grate Cooler for Cement Plant - Rotary Kiln

Working principle of Clinker Grate Cooler: The high-temperature clinker is discharged from the kiln inlet to boring machine, and is distributed along the

Grate Coolers Modern Technology For Cement industry

The grate type cooler is the most suitable cooler for pre-calciner kiln and for kilns with a high outputs Nowadays grate cooler are designed for large kiln capacities up to 10000 t/d It's based on

Cooler Options | World Cement

Ask any cement plant manager about the clinker cooler in his plant, The new erection concept, which utilises a modular design,

D9.2 Analysis of oxyfuel clinker cooler operational performance

performance (efficiency), as well as the potential impacts of CO2–rich cooling gas on clinker quality. The oxyfuel clinker cooler prototype was designed

Grate Cooler - Clinker Cooler | AGICO Grate Cooler In Cement Plant

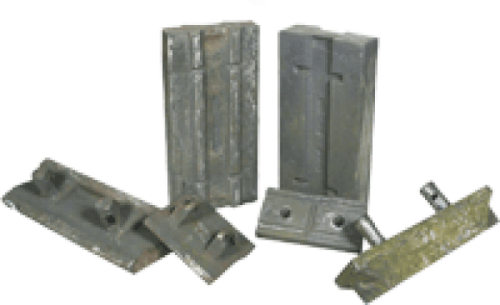

Grate cooler consists of upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan. Of these devices, grate bed is the most important part, mainly composed of overlapping rows of static and movable perforated grate plates.

Clinker Cooler | AGICO Grate Cooler In Cement Plant

Compared with them, grate cooler is the most suitable one for cement production lines with high outputs and usually designed for large cement kiln capacity

Grate Cooler in Cement Plant

Grate Cooler Working Principle The hot clinker discharged from the rotary kiln falls on the grate bed. Under the push of reciprocating grate plate, the hot

PDF XCC Cooler Grates - magotteaux.comPDF

the patented Bar Grate Design for: • Strong resistance to abrasion. • «Self-protecting» design of grate. Our «extras»: cast FMR56 alloy + Xcc® to resist: • Wear. • Temperature. • Cracks. • Superiority coefficient: from 2 times better. Keep cool? Yes, we can! cooler grates Our «extras»: cast FMX250 alloy + Xcc® to resist:

+86-21-63353309

+86-21-63353309

Leave a Comment