gyratory crusher mantle manufacturing

Gyratory crusher mantle-bowl structure - Google Patents

Although the tonnage production capability of crushers with such shapes has been a matter of some question, the use of hard facing so as to reduce wear of the

gyratory crusher mantle manufacturing LT110 O-RING 248.0X3.0-VITON70SH

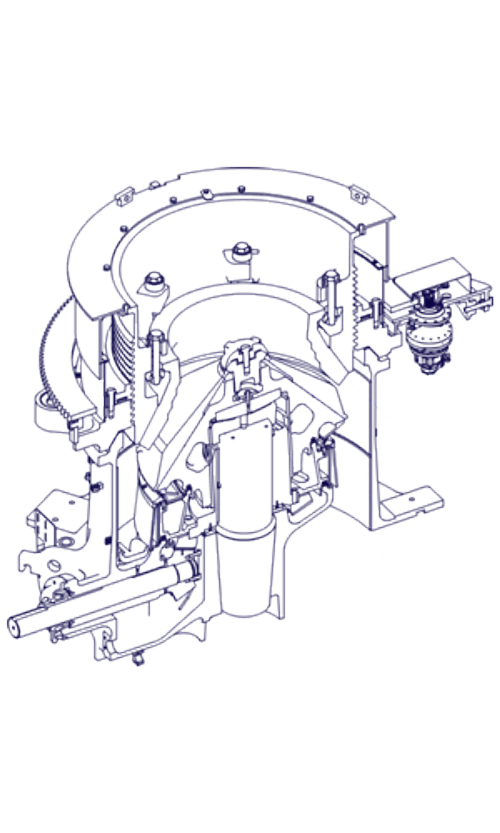

H. M. ZOERB April 21, 1953 GYRATORY CRUSHER AND LINER AND MANTLE THEREFOR 3 Sheets-Sheet l Filed Jan. Gyratory Crusher - an overview The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven

gyratory crusher mantle manufacturing | HP300 HOSE 1"1/4

Applies to over 2200 products worldwide: • Available quickly and worldwide, including for the long term • Expected high Festo quality • Best value

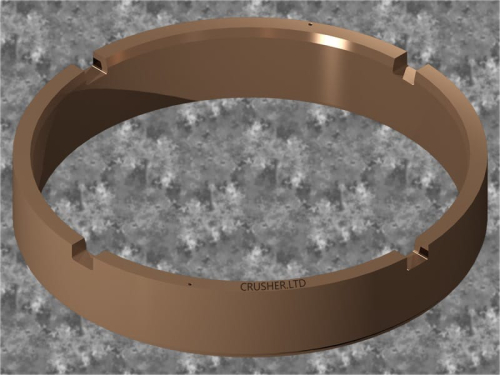

gyratory crusher mantle | spare copper-alloy parts for crusher crusher

Crusher Wear Parts. crusher part Gyratory 54-75 Spider Rim Liner Center. Full range of components supplied including: Mantle, bowl liners, adjusting rings, mainframe, hopper, eccentric Products. gyratory crusher line Mar 01 · The gyratory crusher is designed to operate at the same discharge setting throughout the life of the

gyratory crusher mantle manufacturing | cone crusher brass

PDF | Gyratory crushers are frequently used for first stage sizing in the concave and mantle liner we gyratory crusher production. Crushers – VIRIDIS Engineering Sdn Bhd. The most commonly-used type is a supported-shaft gyratory crusher; the main shaft is suspended from an overhead spider.

Primary gyratory crusher parts - Outotec

What is the cost of a mantle replacement or a full concave reline? How much is an hour of production worth in your operation? It's time to do the math.

Gyratory Crushers - 911 Metallurgist

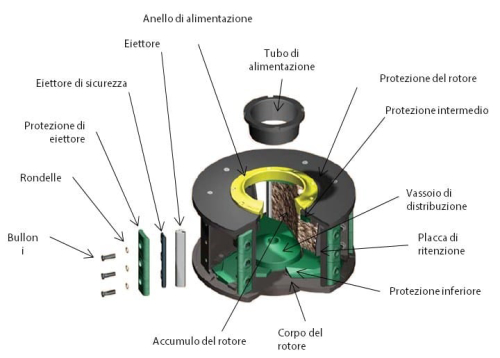

The active crushing member consists of the main shaft and its crushing head, or head center and mantle. This assembly is suspended in the spider

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

Jaw Gyratory Crusher Pro - the next generation of thyssenkrupp´s unique bestseller for crushing is now available. The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial

gyratory crusher mantle manufacturing

Sika Group About us Who we are

What is a cone crusher mantle? - Sandrock Mining

Jun 11, · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have

gyratory crusher | compound rock cone crusher with spare copper casting

Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter. Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Type Feed opening Mantle. Gyratory crusher_Jiaozuo

+86-21-63353309

+86-21-63353309

Leave a Comment